HEPA Box in the microbiology industry is an important device to help maintain ISO Class 5 cleanliness level in sensitive areas such as sterile operating chambers or microbiological filling. With the ability to effectively filter air and distribute a stable flow of clean air, HEPA Box ensures an environment that meets GMP and ISO 14644 standards.

- 1. ISO Class 5 in Microbiology: Why is it mandatory?

- 2. What is a HEPA Box and how does it work?

- 3. Standard HEPA Box Design for Microbiology Use

- 4. HEPA Box Applications in Microbiological Cleanrooms

- 5. Technical Considerations for Installing a HEPA Box

- 6. Frequently Asked Questions

- 7. Contact for Consultation - Choose the Right HEPA Box for Your Microbiology Room

In the biological research and production environment – where every dust particle, every microorganism can affect the results and quality of the product – the HEPA Box solution in the microbiology industry plays a key role. This device not only ensures the removal of more than 99.97% of extremely small particles but also helps maintain a sterile environment, prevent cross-contamination and ensure compliance with strict cleanroom standards. In this article, VCR helps you understand the structure, operating principles and practical benefits of HEPA Box in the field of microbiology – from laboratories, vaccine production to areas handling cells and bacteria.

1. ISO Class 5 in Microbiology: Why is it mandatory?

In microbiological environments, the working area must be strictly controlled to avoid cross-contamination and incorrect test results. According to ISO 14644-1, ISO Class 5 cleanroom conditions require that the number of airborne particles ≥ 0.5 µm does not exceed 3,520 particles per cubic meter-a highly stringent threshold.

Key areas that must meet ISO 5 standards in microbiology cleanrooms:

- Aseptic workbenches (used for microbial culturing or sensitive testing)

- Media preparation areas

- Filling and packaging areas for microbial products

- Inside pass boxes used for transferring test samples

Maintaining ISO 5 conditions is not only critical for product safety but also a mandatory requirement under GMP-WHO, GMP-EU, and microbiological testing regulations.

Consequences of failing to meet ISO Class 5:

- Cross-contamination between microbial samples → invalid test results

- Increased risk of batch rejection, especially for vaccines or biological products

- Failed GMP validation, which can affect product licensing and export approvals

In such conditions, a HEPA Box becomes an indispensable solution-helping to locally distribute clean air, stabilize pressure, and maintain ISO 5 classification at critical points in microbiology laboratories.

See more: How to test HEPA Box performance with DOP test

2. What is a HEPA Box and how does it work?

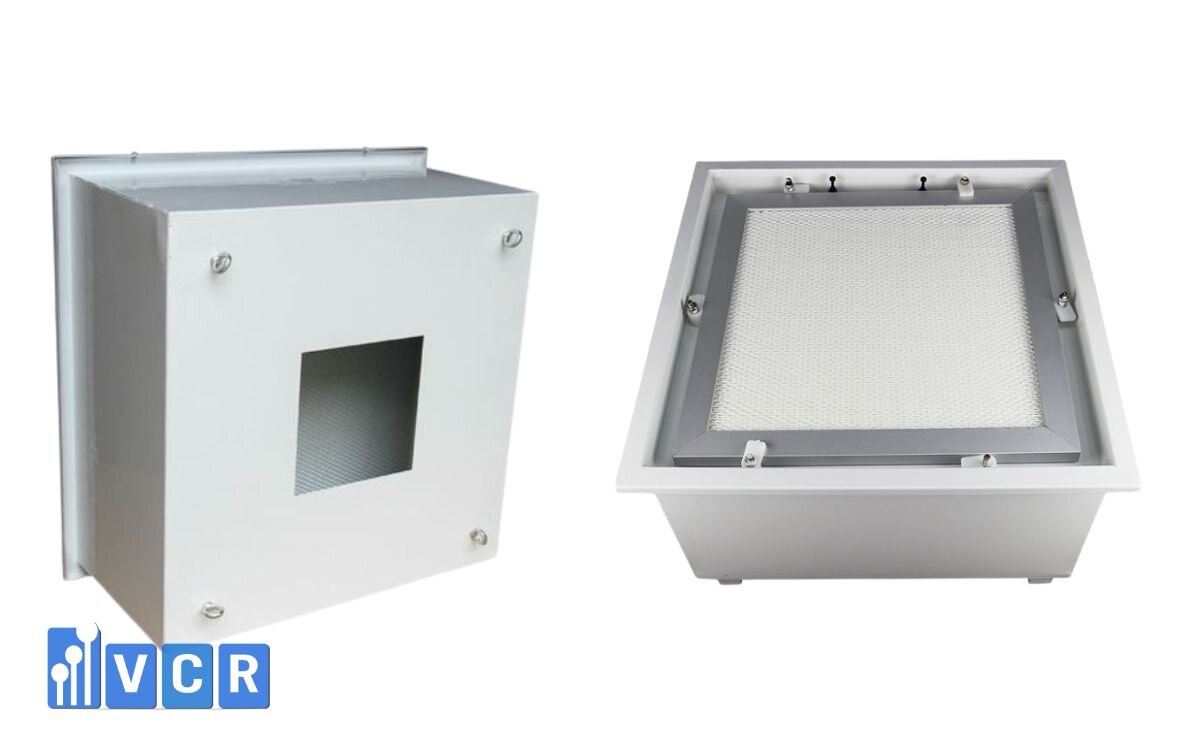

A HEPA Box is a localized clean air distribution device, pre-integrated with a HEPA filter and typically installed in ceiling panels of cleanrooms. Unlike FFUs (Fan Filter Units), which have built-in fans, a HEPA Box relies on pre-treated air from the central HVAC system, filtering it through a HEPA filter to remove dust and microbial contaminants.

Structure and working principle:

- Clean air enters through a duct connection, either flexible or rigid.

- Air passes through an H14 HEPA filter (EN 1822 standard), removing up to 99.995% of particles ≥ 0.3 µm.

- The filtered air is evenly dispersed in a laminar flow by a diffuser panel, minimizing turbulence in the working area.

Key advantages of HEPA Boxes in microbiology applications:

- Virtually silent operation due to the absence of an internal fan

- No electrical power required, making installation and operation simple

- Compact design, ideal for rooms with low ceilings or space limitations

- Easy maintenance with filter replacement accessible from below the ceiling or via inspection hatches

Due to the need for stable, particle-free airflow with minimal disturbance, HEPA Boxes are ideal for environments requiring ISO Class 5 but where FFUs are impractical or unnecessary.

See more: Latest price list of HEPA BOX used in medical clean rooms

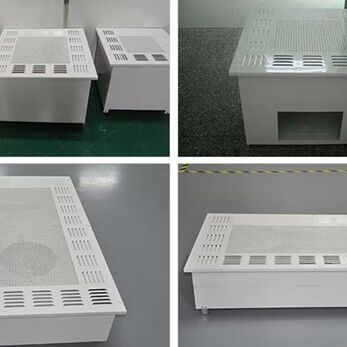

3. Standard HEPA Box Design for Microbiology Use

To meet the strict contamination control requirements of ISO Class 5 environments, HEPA Boxes are built with specialized components optimized for consistent and efficient clean air distribution.

Key components and technical specifications:

|

Component |

Standard Specifications |

|

HEPA Filter |

H14 (EN 1822) - ≥ 99.995% efficiency at 0.3 µm |

|

Housing Frame |

304 stainless steel (corrosion-resistant) or powder-coated steel |

|

Diffuser Panel |

Even airflow dispersion; reduces turbulence and pressure drop |

|

Air Duct Connection |

Circular or square inlet, commonly DN200-250 in size |

Expert recommendation: Choose a HEPA Box with an integrated pressure port to easily monitor pressure differentials and schedule timely filter replacements.

Design features tailored for microbiological use:

- Smooth, easy-to-clean surfaces with no crevices that harbor contaminants

- Option for 316L stainless steel in more demanding environments

- Airtight construction to prevent leaks at the filter frame interface

This design not only ensures high-efficiency air filtration but also complies with GMP, GLP, and ISO 14644 standards-making it highly suitable for critical microbiology applications.

4. HEPA Box Applications in Microbiological Cleanrooms

In pharmaceutical plants, microbiology labs, or sterile testing areas, HEPA Boxes are commonly used as localized filtration solutions, especially effective in compact spaces or where FFUs cannot be installed.

Typical application areas:

- Small aseptic work zones: where FFUs cannot be used or silent operation is preferred

- Airlocks and pass boxes: for clean sample transfer between clean zones

- Weighing rooms for microbial materials: to avoid cross-contamination during material handling

Quick comparison: HEPA Box vs. FFU

|

Criteria |

HEPA Box |

FFU (Fan Filter Unit) |

|

Air Source |

Supplied by central HVAC |

Built-in fan generates airflow |

|

Installation |

Compact and flexible |

Requires higher ceiling space |

|

Noise Level |

Very low, virtually silent |

Audible fan noise during operation |

|

Maintenance |

Simple (filter replacement only) |

Includes fan checks and servicing |

When to choose HEPA Box instead of FFU:

- When low noise levels are essential in microbiology procedures

- When the HVAC system already provides sufficient airflow

- When the ceiling height or space is limited

With its compact size, quiet operation, and high filtration efficiency, the HEPA Box is the ideal solution for sensitive and space-restricted zones within microbiological cleanrooms.

See more: HEPA Filter Terminal Box: A Guardian of Clean Air in Controlled Environments

5. Technical Considerations for Installing a HEPA Box

To ensure optimal filtration performance and maintain ISO Class 5 conditions, HEPA Box installation must follow strict technical standards and industry recommendations.

Key factors to consider:

- Calculate the correct airflow

Before installation, determine the standard airflow based on the room’s size and required cleanliness level. ISO 5 typically requires 240-360 air changes per hour, depending on the room type. - Use airtight sealing gaskets

The entire HEPA Box frame should be sealed with silicone or EPDM gaskets to prevent air leakage. Apply specialized sealants to block any gaps that could allow microbial intrusion. - Flexible duct connections with expansion joints

When connecting to the duct system (flexible or rigid), use vibration-dampening flexible joints to prevent mechanical vibrations from affecting the airtight seal or alignment. - Include pressure monitoring devices

Equip the HEPA Box with an analog differential pressure gauge or digital sensor to monitor filter performance. A pressure rise beyond the recommended threshold indicates the need for filter replacement.

Expert tip from VCR:

Always perform smoke tests or leak testing after installation-especially in microbiology areas that require high ISO classifications.

Proper installation not only ensures effective filtration but also extends equipment lifespan, reduces maintenance costs, and guarantees compliance with GMP/GLP standards during cleanroom validation.

See more: The Indispensable Role of HEPA Boxes in Pharmaceutical Cleanrooms

6. Frequently Asked Questions

Does a HEPA Box provide ISO 5 compliance?

Yes. When connected to a stable HVAC system with appropriate air pressure, a HEPA Box equipped with an H14 filter can maintain ISO Class 5 conditions at the point of use. It is particularly effective in localized areas like airlocks, small workstations, or pass boxes.

How often should the HEPA filter in a HEPA Box be replaced?

Filter replacement depends on usage frequency and the cleanliness of incoming air. On average, HEPA filters should be replaced every 12-24 months. However, it is best to:

- Monitor differential pressure regularly using a gauge or sensor

- Replace the filter once pressure exceeds the manufacturer’s recommended limit (usually 250-450 Pa)

Can HEPA Boxes and FFUs be used together?

Absolutely. Many microbiology facilities use FFUs in primary work zones (e.g., filling lines or sample preparation) for active airflow control, while HEPA Boxes are installed in supporting areas such as airlocks, gowning rooms, and buffer corridors to save cost while still meeting ISO standards.

7. Contact for Consultation - Choose the Right HEPA Box for Your Microbiology Room

Maintaining an ISO Class 5 environment depends not only on cleanroom design but also on selecting the right air filtration equipment-placed in the right locations and meeting the correct standards.

Are you building or upgrading a microbiology facility?

Let VCR’s team of experts help you select a HEPA Box tailored to your HVAC system, room layout, and regulatory requirements.

We offer complete solutions: HEPA Box units - installation drawings - airflow layout consulting.

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR