HEPA Box is a specialized air filtration device in HVAC systems, helping to remove fine dust and microorganisms, and maintain cleanliness levels in accordance with standards such as ISO 14644-1, HACCP, and ISO 22000. VCR – a leading provider of HEPA Box in Vietnam – offers optimal air filtration solutions for clean food production lines.

1. What is a HEPA Box filter?

A HEPA Box filter is a specialized air purification unit, usually installed at the terminal points of the central air conditioning (HVAC) system in cleanrooms. Its function is to eliminate fine dust particles, microorganisms, and suspended air particles, thus maintaining an absolutely clean environment as required in the food industry.

In clean food production processes, the HEPA Box plays extremely important roles by:

-

Preventing microbial contamination and fine dust from entering production areas

-

Maintaining cleanliness levels according to cleanroom standards such as ISO 14644-1, HACCP, ISO 22000

-

Ensuring food safety throughout processing, packaging, and storage

The basic structure of a HEPA Box includes:

-

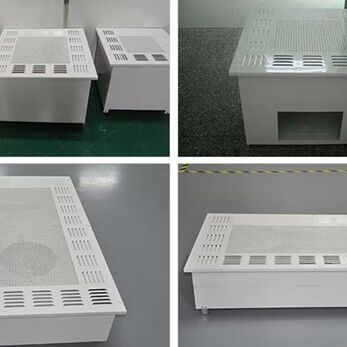

Box housing: made from electrostatic powder-coated steel or stainless steel

-

Filter clamp tray: to firmly fix the HEPA filter element

-

HEPA filter: often with filtering efficiency ≥ 99.97% for particles ≥ 0.3 micron

-

Plenum box (air chamber): to evenly distribute airflow

-

Round or square duct collar: to connect with the central air duct system

The HEPA Box can also be designed with additional features such as airflow control valves, differential pressure sensors, or integrated UV sterilization, depending on the requirements of the food factory.

Read more: Latest price list of Hepa box used in food factory

2. Why do clean food production lines need HEPA Boxes?

In the food industry, especially factories producing dairy, beverages, functional foods, or packaged foods, a clean environment is critical to ensure product quality.

HEPA Boxes help tightly control air quality during production by:

-

Filtering fine dust and bacteria: HEPA Boxes can capture extremely small particles, including bacteria, molds, and fine dust — all potential contaminants

-

Maintaining local sterile conditions in key areas such as filling rooms, raw material weighing rooms, and packaging rooms

-

Preventing cross-contamination: HEPA Filters combined with positive pressure systems help to block polluted air from entering, creating clean-to-less-clean airflow barriers

-

Reducing food safety risks: Controlling airborne microorganisms is a mandatory requirement under standards like HACCP and ISO 22000

-

Ensuring compliance: Using HEPA Boxes helps factories meet regulatory inspections, protect their brand, and safeguard consumers

In some sections, cleanroom classes like Class 1000 to 10,000 are required, depending on the area. Factories manufacturing powdered milk, beverages, supplements, etc., almost always require HEPA Boxes in their HVAC systems.

Read more: Verifying HEPA Box Performance for Cleanroom Suitability

3. Criteria for choosing a reputable HEPA Box supplier

Choosing the right HEPA Box supplier affects not only air filtration performance but also the ability of a business to meet food safety standards. Below are four key criteria that food factories should consider:

| Criterion | Details |

|---|---|

| Industry experience | The supplier should have experience in cleanroom projects for the food industry and understand requirements for clean zones, transitional zones, pressure differentials, airflow, etc. |

| Product quality | HEPA Boxes must meet filtering standards (e.g. EN 1822), be leak-tested before shipping, and use materials resistant to humidity, corrosion, and easy to clean. |

| Technical services | A reputable supplier should support system design, installation, performance testing (e.g. DOP leak test), differential pressure measurement, and routine maintenance. |

| Certifications & standards | Products and processes should meet ISO 9001, use materials certified for food safety (e.g. FDA, EU 10/2011), and conform to industry norms. |

Read more: HEPA Box Installation Best Practices

4. VCR – Supplier of HEPA Boxes for clean food manufacturing

With nearly 10 years of experience in the cleanroom equipment field, VCR has established itself as a trusted partner for many major food and beverage companies. We not only supply quality products but also assist customers in building and operating standard cleanrooms.

Notable features of HEPA Boxes for clean food factories supplied by VCR:

-

A variety of sizes & airflow capacities: suitable for everything from small packaging rooms to large production areas

-

Optional integration of UV and sensors: enhancing sterilization and monitoring of filtration performance

-

Custom fabrication: tailored to the installation space and cleanroom standards of each sector

-

Food-safe materials: 304/316 stainless steel or powder-coated steel, easy to clean and corrosion resistant

VCR commits that each HEPA Box product is leak-tested before delivery and comes with full technical documentation and GMP/ISO 14644 compliant installation instructions.

5. Common applications of HEPA Boxes in the food industry

In clean food factories, HEPA Boxes are essential in areas requiring high cleanliness, areas prone to cross-contamination, or zones that directly contact the product. Proper installation helps manage air quality and maintain standards like ISO, HACCP, GMP.

Typical areas using HEPA Boxes include:

-

Packaging rooms: where finished products are in contact with packaging — sterile conditions are critical

-

Mixing and filling areas: such as in beverage or liquid food plants — HEPA Boxes keep air at filling nozzles clean

-

Raw material storage areas: to reduce dust and contaminants in ingredient storage

-

Dry ingredient weighing rooms: zones with high risk of dust dispersion; integrating local negative pressure plus HEPA Boxes helps control airflow

Read more: HEPA Filter Terminal Box: A Guardian of Clean Air in Controlled Environments

6. Frequently Asked Questions (FAQ)

Q: Can a HEPA Box be installed outdoors?

A: Not recommended. HEPA Boxes are designed to operate efficiently in controlled, enclosed cleanroom or HVAC environments. Outdoor installation exposes the system to moisture, coarse dust, and reduces lifespan and filtration performance.

Q: How often should the HEPA filter element be replaced?

A: Typically between 6 – 12 months, depending on dust load and usage intensity. More precise timing can be determined by monitoring differential pressure across the filter via a manometer.

Q: Does VCR support installation and validation of HEPA Boxes?

A: Yes. VCR offers full services including:

-

Technical consulting for food industry cleanrooms

-

Correct airflow installation and balancing

-

Performance testing, leak testing (DOP)

-

Regular maintenance and filter replacement

Need consulting on air filtration solutions for your food factory? VCR’s technical team is ready to support you onsite — ensuring your HVAC system operates efficiently and meets food hygiene standards!

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Dat VCR