At the packaging area of cosmetics – where products directly interact with the environment before completion – controlling dust and microorganisms becomes a vital factor. A HEPA Box is the “final air-filtration barrier,” helping to maintain GMP-standard clean air and protect product quality.

- 1. Brief introduction to the role of HEPA Box in a cosmetic packaging room

- 2. What is a HEPA Box? Application in the cosmetic industry

- 3. Criteria for selecting a GMP-compliant HEPA Box for the cosmetic industry

- 4. VCR – A reputable supplier of HEPA Boxes for cosmetic factories

- 5. Consultation & supply process of HEPA Boxes at VCR

- 6. Benefits when choosing VCR as your HEPA Box supplier

- 7. FAQ – Frequently asked questions

1. Brief introduction to the role of HEPA Box in a cosmetic packaging room

In the cosmetic production process, the packaging stage is one of the most crucial steps, where the product comes into direct contact with the environment before being finalised. Therefore, controlling airborne microorganisms and dust becomes a matter of survival in ensuring product quality and consumer safety.

In particular, according to GMP standards in the cosmetics sector, the packaging area is often classified in high-cleanliness grades (Grade A/B). It demands that the air environment reach maximum purity. Any infiltration of dust, contaminants or microbes can ruin the entire batch.

The cleanroom HEPA Box is a device used as the “final filter barrier” before the air is introduced into the clean production zone. Thanks to its ability to retain up to 99.99% of particles sized ≥ 0.3 µm, the HEPA Box helps maintain positive pressure and ensures only clean air flows in.

Equipping a HEPA Box is not only a technical requirement but also a corporate commitment to product and brand quality in the cosmetics industry.

Read more: Latest price list of Hepa box used in Cosmetic factory

2. What is a HEPA Box? Application in the cosmetic industry

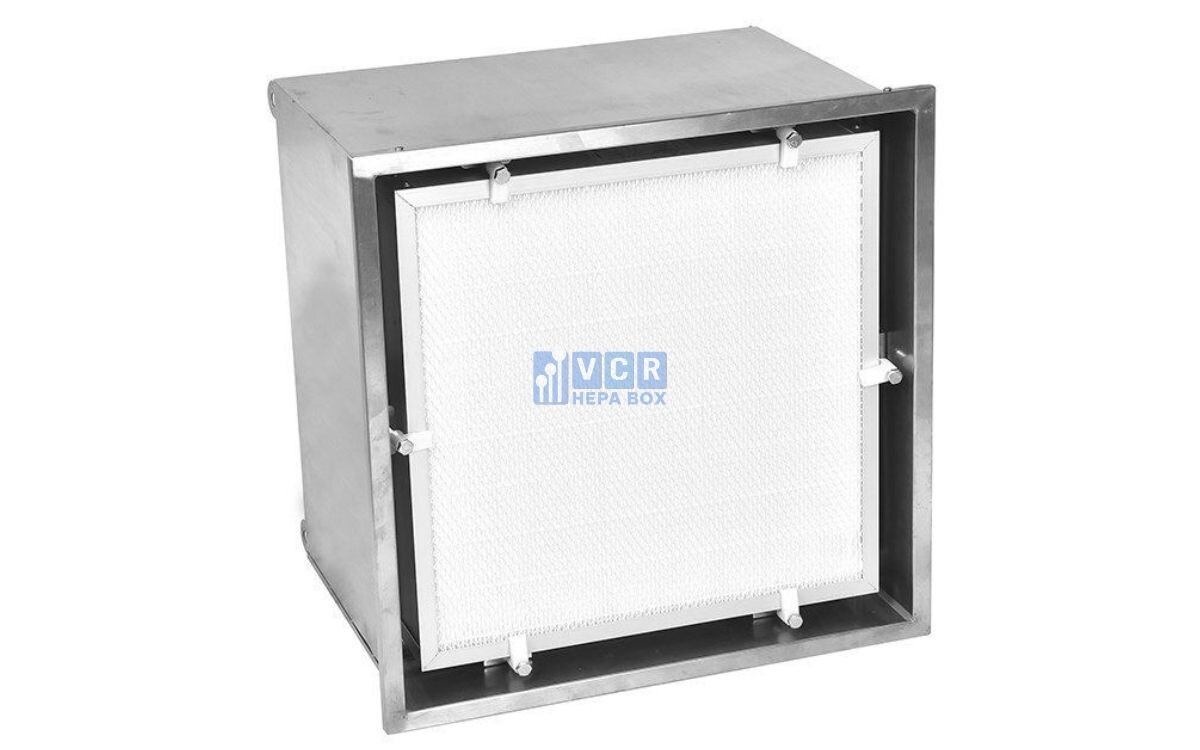

A HEPA Box (also called Terminal HEPA Filter Box) is an air-filtration device used in cleanroom systems, especially at the end of the duct system before air is delivered into the production environment. The unit integrates a HEPA or ULPA filter – high-efficiency filters that remove fine dust particles and ultra-small microorganisms.

The basic structure of a HEPA Box includes:

-

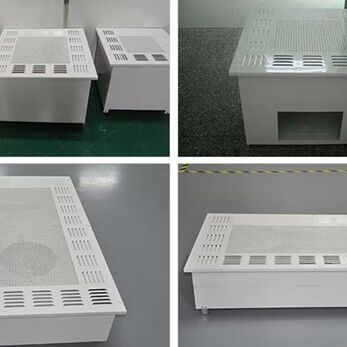

Housing box: typically made of electro-powder-coated steel or stainless steel; highly durable and corrosion resistant.

-

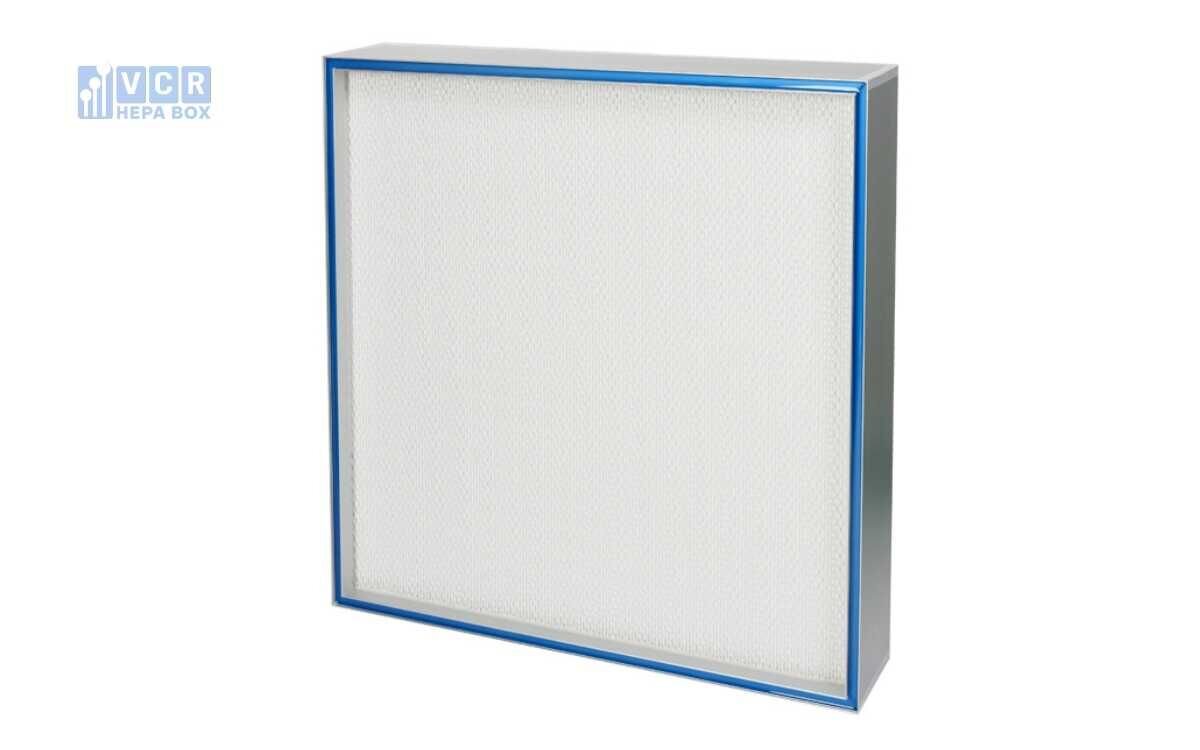

HEPA filter: minimum efficiency ≥99.99% for particles ≥0.3 µm.

-

Diffuser sheet: helps distribute the air evenly within the room.

-

Differential pressure gauge (optional): monitors the filter’s clogging status.

-

Duct connection: connects to the AHU or HVAC system.

Applications in cosmetic packaging rooms – typically at Grade A/B areas:

In cosmetic manufacturing plants, areas like:

-

Finished-product packaging rooms

-

Filling/dispensing zones

-

High-grade changing rooms

... all require cleanliness at Grade B or higher according to GMP-WHO standards. These are high‐risk areas for microbial contamination, thus requiring effective and stable air filtration systems.

The HEPA Box is installed on the ceiling or at the end of the duct to ensure the air has been treated and filtered one final time before entering the production environment. This enables:

-

Stable positive pressure inside the clean room

-

Cleanliness meeting required standards

-

Minimising cross-contamination between zones

Why must HEPA Boxes be used in cosmetic factories?

-

Compliance with GMP standards: Cosmetic manufacturing plants wishing to gain GMP certification are required to have environmental control systems; HEPA Boxes are a key component.

-

Ensuring product safety: They eliminate the risk of contamination from dust and microbes, which could affect the quality of cosmetics.

-

Minimising product recall risk: A sub-standard air filtration system can lead to large-scale microbial contamination – with severe brand and financial consequences.

-

Required during audits by regulators and international partners.

In summary, a HEPA Box is not just a technical device but also an “insurance policy” for product quality and the reputation of a cosmetic manufacturing plant in the market.

Read more: HEPA Box Installation Best Practices

3. Criteria for selecting a GMP-compliant HEPA Box for the cosmetic industry

Selecting the right HEPA Box not only helps maintain air-filtration performance, but also ensures compliance with strict environmental-control demands in a clean room for cosmetics. Below are key criteria to consider:

High filtration efficiency ≥ 99.99% for particles ≥ 0.3 µm.

The HEPA Box should include HEPA or ULPA filters capable of removing almost all particles and microbes from the air. This level of efficiency will prevent contamination risks that affect cosmetic product quality.

Appropriate airflow rate and capacity aligned with clean-room grade (A/B/C).

Depending on the clean-room classification (per GMP) of each area in the factory, the HEPA Box must ensure properly calculated airflow to maintain positive pressure and air-changes per hour (ACH) by standard. For example:

- Grade A: requires high airflow and unidirectional (laminar) flow.

- Grade B/C: requires turbulent but still stable airflow.

Integration of a differential pressure gauge and uniform air distribution system.

A pressure gauge helps monitor filter clogging for timely replacement and prevent pressure drop or filtration efficiency drop. Meanwhile, a plenum (air chamber) that distributes air uniformly across the filter surface helps reduce dead zones and ensures consistent clean-room conditions.

Design compatibility with the factory’s panel ceiling system.

In GMP-standard cosmetic plants, most ceilings are built with flat, sealed panels. The HEPA Box must have standard modular design, easy to install flush with the ceiling or suspended, without affecting existing structure. Especially, it must be compatible with LED lights, sprinkler heads, auxiliary ducts…

Materials resistant to chemicals and easy to clean.

The HEPA Box must be made from materials like stainless steel (Inox 304/316) or electro-powder-coated steel, capable of resisting chemical cleaners used in clean rooms. Surfaces inside and out should be smooth, curved at corners, non-dust-retaining, and easy to wipe clean – meeting the hygiene requirements of the cosmetics industry.

Read more: HEPA Filter Terminal Box: A Guardian of Clean Air in Controlled Environments

4. VCR – A reputable supplier of HEPA Boxes for cosmetic factories

VCR is one of the pioneering companies in Vietnam specialising in supplying equipment and solutions for GMP-standard clean rooms, especially in the cosmetics, pharmaceuticals, functional food and electronics industries. With over 10 years of experience, VCR has become a trusted partner of hundreds of factories and production lines, both domestic and international.

They not only supply equipment but accompany customers from consultation, design, installation through to validation and operation. Their HEPA Boxes are manufactured with strict quality control, using high-grade materials, ensuring tightness, high filtration efficiency and outstanding durability. Each product is 100% DOP-tested before leaving the factory, and comes with full CO (Certificate of Origin), CQ (Certificate of Quality).

VCR’s commitments:

-

Products meet GMP and ISO 14644 standards.

-

24/7 technical engineer support.

-

Equipment warranty up to 18 months.

-

Support for post-installation filtration testing and validation.

VCR does not just sell equipment – they provide optimal and integrated solutions for all scales of cosmetic manufacturing plants that need GMP-compliant clean-air control.

Read more: Verifying HEPA Box Performance for Cleanroom Suitability

5. Consultation & supply process of HEPA Boxes at VCR

With the aim of delivering optimal and streamlined solutions to cosmetic factories, VCR builds a consultation and supply process for HEPA Boxes under GMP standards that is clear, transparent and professional:

-

Site survey – Technical consultation based on GMP requirements

Upon receiving a customer request, VCR’s engineering team visits the factory to survey the actual site, HVAC system and layout of the clean-area. From there VCR offers a HEPA Box design appropriate to:-

Clean-room class (Grade A/B/C)

-

Required airflow

-

Ceiling size and existing duct network

-

GMP audit documentation requirements

-

-

Quotation – Production – Delivery – Integrated installation

After the technical plan is agreed, VCR proceeds with:-

Manufacturing HEPA Boxes per custom requirements: size, airflow, installation type (flush/ceiling type), material.

-

Quality checks: leakage test, filtration efficiency test.

-

On-site delivery and professional installation (if requested)

-

Integrating differential pressure gauge, maintenance access door or additional accessories if needed.

-

-

Operation guide – Periodic maintenance – Post-installation air-filtration testing

After installation, VCR continues to accompany the customer through:-

Training factory personnel on basic operation and maintenance.

-

Providing scheduled maintenance: filter replacement, cleaning surfaces, checking pressure gauge.

-

Offering post-installation filtration testing (DOP test, performance check, pressure monitoring) to ensure the system is compliant before production starts.

-

This process ensures that the equipment is not only technically suitable but also synchronised with the quality-management procedures of a GMP-standard cosmetic factory.

Read more: Structure and application of HEPA Box for ISO 5 clean room

6. Benefits when choosing VCR as your HEPA Box supplier

Choosing the correct clean-room equipment supplier plays a crucial role in building and operating a cosmetic-production line that meets GMP standards. Here are reasons why many leading cosmetic factories trust VCR as their HEPA Box and clean-air solution partner:

-

Effective control of particulates and microorganisms according to GMP standards: VCR’s HEPA Boxes are designed specifically for clean rooms in the cosmetics industry. Integrating high-quality HEPA/ULPA filters, the product ensures maximal retention of dust particles and bacteria, helping customers meet the allowable particulate concentrations as per Grade A/B/C classification.

-

Turn-key solution for cosmetic factories: Not only supplying HEPA Boxes alone, VCR also designs and implements a complete solution including:

-

AHU (Air Handling Unit) for clean-air processing

-

Ducting system to distribute air to required areas

-

FFU, LAF, Pass Box – supportive devices controlling airflow and material transfer

This integrated approach helps optimise cost while ensuring technical consistency and operational performance across the factory’s clean-room system.

-

-

On-site technical service – Audit support: VCR’s experienced technical team is always ready to:

-

Survey – consult – design to standard

-

Install – balance – test filtration performance (DOP, airflow)

-

Guide operation and periodic maintenance

-

Support technical documentation, internal GMP audits or regulatory inspections.

-

Choosing VCR means choosing comprehensive assurance in the journey of building and operating a clean, efficient, GMP-certified cosmetic production line.

Read more: Supplier of GMP‑Standard Cleanroom HEPA Box Filters

7. FAQ – Frequently asked questions

Does a HEPA Box need periodic replacement? How often?

Yes. The HEPA filter inside the HEPA Box gradually accumulates dust and its efficiency decreases over time. Replacement cycles typically range from 12 to 18 months, depending on:

-

Intensity of HVAC operation

-

Quality of incoming air

-

Maintenance and production-environment conditions

Regular monitoring of differential pressure or filter impedance will help determine the exact time for replacement.

Can a HEPA Box be installed on a gypsum-board ceiling?

Yes. However, note the following:

-

The gypsum ceiling must be able to support the load of the HEPA Box (typically 10–20 kg).

-

A steel or aluminium frame reinforcement is recommended to ensure safety.

-

Air-sealing around the installation site must be ensured to avoid air leakage.

VCR provides surveying service and proposes installation methods suitable for various ceiling types, including gypsum systems.

Does VCR support post-installation HEPA testing?

Yes. VCR offers integrated services for equipment testing and calibration after installation, including:

-

DOP tests to check actual filter efficiency of HEPA.

-

Airflow evaluation, velocity and distribution checks in the clean-area.

-

IQ/OQ documentation serving internal GMP audits or regulatory partner inspections.

Regular testing helps maintain filtration performance and ensures compliance with GMP standards in the cosmetics industry.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Dat VCR