HEPA Box is an important terminal air filtration device in clean room systems, widely used in cosmetic factories to ensure the production environment meets ISO 22716 (GMP) standards. With the ability to filter dust and microorganisms up to 99.995%, HEPA Box helps maintain pure air, stable positive pressure and prevent cross-contamination.

- 1. What is a HEPA Box? Why is it essential in cosmetic manufacturing?

- 2. Common Types of HEPA Boxes for Cosmetic Manufacturing

- 3. Latest HEPA Box Price List for Cosmetic Factories (2025)

- 4. Key Factors Affecting HEPA Box Pricing

- 5. Recommendations for Choosing the Right HEPA Box for Cosmetic Manufacturing

- 6. Quick Comparison: HEPA Box vs. FFU in Cosmetic Cleanrooms

- 7. Frequently Asked Questions (FAQs)

- 8. Get an Accurate HEPA Box Quote for Your Cosmetic Facility

1. What is a HEPA Box? Why is it essential in cosmetic manufacturing?

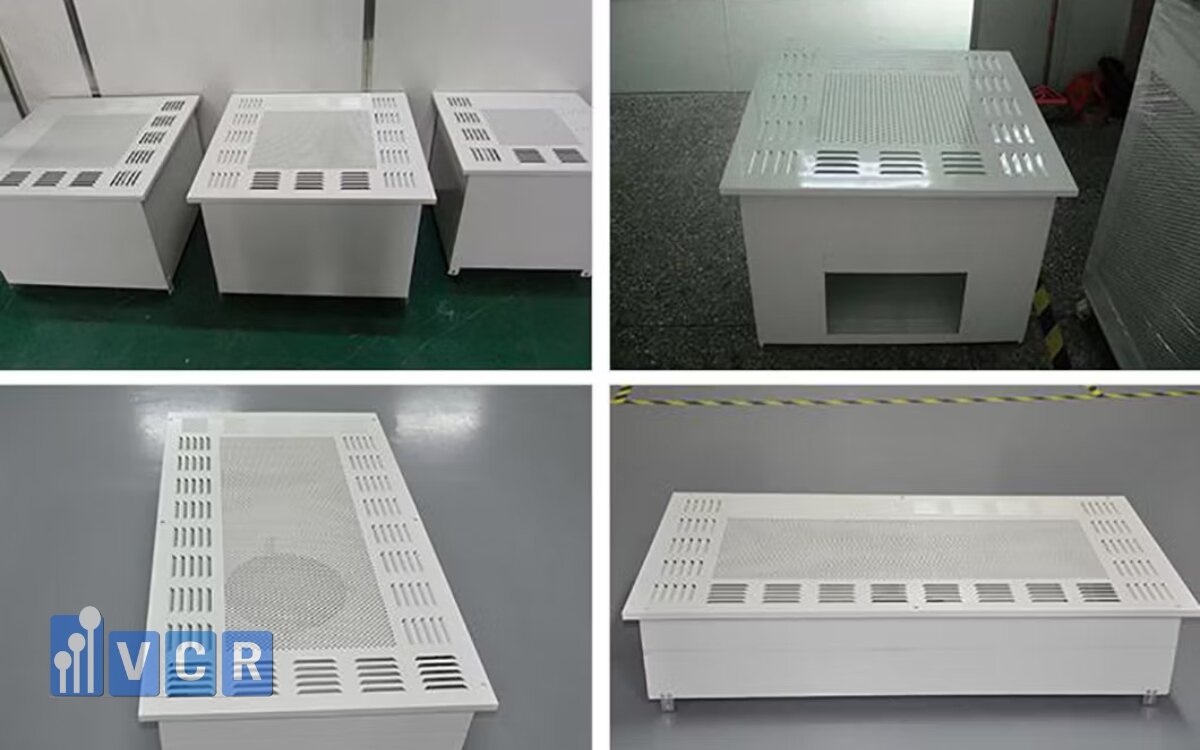

A HEPA Box is a terminal air filter device typically installed in cleanroom ceilings. It delivers clean, filtered air directly into production zones, ensuring compliance with air quality standards. This equipment is a crucial part of the HVAC system, especially in industries with strict contamination control requirements such as cosmetics, pharmaceuticals, and food processing.

Why do cosmetic factories need HEPA Boxes?

In cosmetic production, hygiene, stability, and product purity are top priorities. A HEPA Box helps by:

- Filtering airborne dust and microorganisms with 99.97% to 99.995% efficiency, depending on whether it uses H13 or H14 filters.

- Maintaining positive pressure to prevent cross-contamination between production areas (e.g., filling and packaging zones).

- Delivering clean air that meets ISO standards, ensuring compliance with ISO 22716 (Cosmetic GMP).

Areas where HEPA Boxes are required under ISO 22716:

According to ISO 22716 guidelines, HEPA Boxes are typically required in the following zones:

- Filling and packaging rooms

- Raw material handling zones

- Weighing and dispensing rooms

- Airlocks between production areas

- QC laboratories or inspection rooms

Depending on the required cleanroom class (ISO 5 to ISO 8), the type of HEPA Box and filtration grade will vary to ensure both product safety and GMP audit compliance.

2. Common Types of HEPA Boxes for Cosmetic Manufacturing

Depending on the cleanroom class, production layout, and budget, cosmetic factories can choose from several HEPA Box types:

|

HEPA Box Type |

Technical Specs |

Key Advantages |

Recommended Application |

|

Basic H13 HEPA Box |

H13 filter - 99.97% efficiency, no damper |

Cost-effective, simple to replace |

Corridors, utility rooms, support areas |

|

H14 HEPA Box with damper & DOP port |

H14 filter - 99.995%, with airflow control and DOP test port |

Enables airflow adjustment and efficiency testing |

Weighing rooms, airlocks, ISO 7 zones |

|

Gel Seal HEPA Box |

H14 filter with gel-sealed frame |

Absolute airtight sealing, high microbial control |

Aseptic filling zones, ISO 5 clean areas |

|

Full Stainless Steel 304 HEPA Box |

304 stainless steel housing, optional ULPA filter |

Corrosion-resistant, suitable for harsh environments |

Microbiology labs, solvent handling areas |

Selection Tips:

- New facilities should consider HEPA Boxes with DOP test ports to ease validation and commissioning.

- High-sterility zones like filling and packaging should use Gel Seal types for airtight performance.

- In areas exposed to corrosive agents (e.g., alcohols, solvents), opt for 304 stainless steel housing for extended durability and hygiene.

See more: HEPA Filter Terminal Box: A Guardian of Clean Air in Controlled Environments

3. Latest HEPA Box Price List for Cosmetic Factories (2025)

|

HEPA Box Type |

Standard Size |

Integrated Filter |

Price Range (VND/unit) |

|

Basic H13 HEPA Box |

610×610×300 mm |

H13 - 99.97% |

2,800,000 - 3,500,000 |

|

H14 HEPA Box with damper + DOP port |

610×610×350 mm |

H14 - 99.995% |

3,800,000 - 5,200,000 |

|

Gel Seal HEPA Box |

610×610×350 mm |

H14 + Gel Seal |

6,000,000 - 8,500,000 |

|

Full Stainless Steel 304 HEPA Box |

610×610×350 mm |

H14 or ULPA |

7,000,000 - 9,500,000 |

Note:

- Prices exclude VAT, filter replacement, transportation, and installation.

- For custom sizes, materials, or bulk orders, please contact VCR for a detailed quote based on your technical drawings.

4. Key Factors Affecting HEPA Box Pricing

The price of a HEPA Box for cosmetic manufacturing can vary significantly depending on technical specifications and order requirements. Below are the five key factors that impact cost:

1. Type of Integrated Filter: H13 vs. H14

- H13 filters (99.97% efficiency) are more affordable and suitable for auxiliary areas like hallways or storage.

- H14 filters (99.995% efficiency) are the industry standard for production zones requiring strict microbial control.

- Some models may include ULPA filters or pre-filters, which increase the overall cost.

2. Housing Material: Powder-coated Steel vs. Stainless Steel

- Powder-coated steel is the most economical but lacks strong corrosion resistance.

- Stainless steel 201 offers moderate corrosion protection but may oxidize over time.

- Stainless steel 304 is premium-grade, highly durable, and easy to clean—ideal for microbiological labs or solvent-heavy environments.

3. Fan Integration (Standalone Air Supply)

- Some HEPA Boxes come with integrated centrifugal fans (similar to FFUs), enabling independent airflow.

- This option adds 30-50% to the cost but is ideal for cleanrooms without central HVAC systems or for zones requiring isolated airflow.

4. Differential Pressure Gauge

- A pressure gauge helps monitor filter condition in real time and ensures GMP compliance.

- Adding this feature increases the price by 300,000 to 600,000 VND, depending on the type (analog or digital).

5. Custom Dimensions (Made to Order)

- If your factory has non-standard ceiling grids, airflow requirements, or space limitations, custom HEPA Boxes are necessary.

- Custom units may cost 10-25% more depending on complexity and quantity ordered.

Tip: To optimize costs, choose different HEPA Box types based on the function of each area—there’s no need to use high-spec models factory-wide unless strictly required.

See more: The Indispensable Role of HEPA Boxes in Pharmaceutical Cleanrooms

5. Recommendations for Choosing the Right HEPA Box for Cosmetic Manufacturing

Choosing the appropriate HEPA Box not only helps optimize investment costs but also ensures compliance with industry standards like ISO 22716 (Cosmetic GMP). Below are practical recommendations based on factory layout and scale:

Packing & Filling Zones: Use HEPA Box with Differential Pressure Gauge

- These are critical areas where microbial contamination risk is high.

- Choose H14 HEPA Boxes with built-in differential pressure gauges for real-time monitoring.

- This helps maintain positive pressure and ensures air cleanliness levels meet ISO Class 7 or ISO Class 5.

Small Factories without Central HVAC: Use HEPA Box with Built-in Fan

- Smaller facilities or retrofitted buildings may lack centralized HVAC systems.

- In such cases, opt for HEPA Boxes with integrated centrifugal fans (mini Fan Filter Units) to generate clean airflow independently.

- This reduces HVAC investment and allows flexible installation in limited spaces.

ISO Class 8 Cleanrooms or Higher: Prioritize H14 Filters

- Although ISO 8 is the least stringent cleanroom level, microbial risks remain high in cosmetics.

- HEPA H14 filters (≥99.995% efficiency) are recommended over H13 to meet audit expectations and contamination control.

- Many auditors require H14 filters in weighing rooms, airlocks, and packaging areas—even in facilities only registered for ISO 8.

Note: For support areas like corridors or buffer zones, basic H13 HEPA Boxes can still be used to reduce costs effectively.

6. Quick Comparison: HEPA Box vs. FFU in Cosmetic Cleanrooms

When designing clean air systems, cosmetic manufacturers often choose between HEPA Boxes and FFUs (Fan Filter Units). Here's a quick side-by-side comparison to help guide your decision:

|

Criteria |

HEPA Box |

FFU (Fan Filter Unit) |

|

Investment Cost |

Lower |

Higher |

|

Self-Supplying Clean Air |

No (unless fan is integrated) |

Yes, built-in centrifugal fan |

|

Ease of Installation |

Easy with standard ceilings |

Depends on ceiling structure |

|

HVAC Compatibility |

Requires central HVAC connection |

Can operate independently |

|

Maintenance |

Simple, filter-only |

Requires motor inspection |

|

Best for |

Centralized HVAC systems |

Small factories or standalone cleanrooms |

Selection Advice:

- If your facility already has a central HVAC system → HEPA Box is a cost-effective choice.

- If you prefer an all-in-one solution → FFU is ideal for independent or small cleanrooms.

See more: Verifying HEPA Box Performance for Cleanroom Suitability

7. Frequently Asked Questions (FAQs)

1. Is a HEPA Box mandatory in cosmetic factories?

→ Yes. If your factory adheres to ISO 22716 or is preparing for a GMP audit, HEPA Boxes are required in clean production zones such as filling, packaging, and weighing rooms.

2. Can I order a custom-sized HEPA Box?

→ Absolutely. VCR offers custom manufacturing of HEPA Boxes based on your required dimensions, filter type, air inlet design, materials, and accessories (fan, damper, DOP port).

3. Should I use H13 or H14 filters for cosmetic production?

→ Based on ISO 22716 and industry practice, H14 (≥99.995% efficiency) is safer and more commonly used in critical zones. H13 may be suitable for technical or secondary areas.

4. How often should HEPA filters be replaced?

→ On average, every 6 to 12 months, depending on:

- Dust and microbial levels in the environment

- Operating hours per day

- Differential pressure readings (if a gauge is installed)

→ If pressure exceeds recommended levels, filters should be replaced immediately to maintain cleanroom classification.

8. Get an Accurate HEPA Box Quote for Your Cosmetic Facility

Are you looking for a HEPA Box that meets ISO 22716 or aiming to reduce cleanroom equipment costs while still passing GMP audits?

VCR’s engineering team is ready to provide 1-on-1 consulting based on your actual facility layout.

We support layout planning, filter grade selection, material choices, and technical specifications.

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR