In modern electronics factories, clean environment control is a key factor to ensure product quality. HEPA Box (HEPA Terminal Box) is an important terminal air filtration device, helping to remove up to 99.99% of fine dust ≥ 0.3 microns, maintaining ISO 5 - ISO 8 cleanliness level. The following article will update the latest price list of HEPA Box

- 1. What is a HEPA Box? Its Role in Electronics Manufacturing Plants

- 2. Common Types of HEPA Boxes Used in Electronics Industry

- 3. Updated HEPA Box Price List for 2025

- 4. Key Factors Affecting HEPA Box Prices

- 5. Technical Notes When Installing a HEPA Box

- 6. HEPA Box vs FFU - Which One Should You Choose?

- 7. Frequently Asked Questions About HEPA Boxes

- 8. Get a Quick & Accurate HEPA Box Quotation

1. What is a HEPA Box? Its Role in Electronics Manufacturing Plants

Definition of HEPA Box

A HEPA Box (also known as a HEPA Terminal Box) is a terminal air filtration device installed in cleanroom ceilings. Its main function is to distribute clean air—filtered through HEPA or ULPA filters—into areas that require strict particle control. This device removes up to 99.99% of airborne particles ≥ 0.3 microns, meeting cleanroom standards from ISO 5 to ISO 8.

A typical HEPA Box may include:

- Air diffuser grid

- Airflow damper

- Differential pressure gauge (optional)

- Housing made of stainless steel or powder-coated steel

Function as a Terminal Filtration Unit

In cleanroom HVAC systems, the HEPA Box serves as a terminal filter, meaning:

- Pre-conditioned air from AHU or PAU enters the HEPA Box

- The HEPA/ULPA filter removes any remaining fine particles

- Clean air is then diffused downward into the production zone through the grid

Thanks to this design, the HEPA Box ensures that only ultra-clean air reaches sensitive products and manufacturing equipment—an essential requirement in precision electronics environments.

Why is the HEPA Box Mandatory in Electronics Manufacturing?

In fields such as:

- SMT (Surface-Mount Technology)

- Semiconductor assembly

- Electronic component testing

… the environment must be extremely clean to avoid product failures due to dust contamination, which can cause short circuits or malfunctions.

Therefore, electronics factories typically require:

- ISO Class 7-5 cleanroom levels, as defined by ISO 14644-1

- Terminal filtration at the point of use → HEPA Box or FFU is mandatory

Not using HEPA Boxes in these areas may result in:

- Mass product defects caused by micro-particles

- Damage to high-precision measuring equipment

- Non-compliance with quality inspection standards

That’s why HEPA Boxes are essential in critical zones such as production lines, inspection areas, and packaging rooms in modern electronics plants.

2. Common Types of HEPA Boxes Used in Electronics Industry

Depending on the application area, cleanliness level, and facility layout, electronics manufacturers choose different types of HEPA Boxes. Below are the 3 most common models:

2.1 Basic HEPA Box (Non-Fan Type)

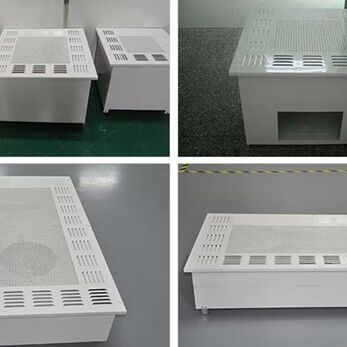

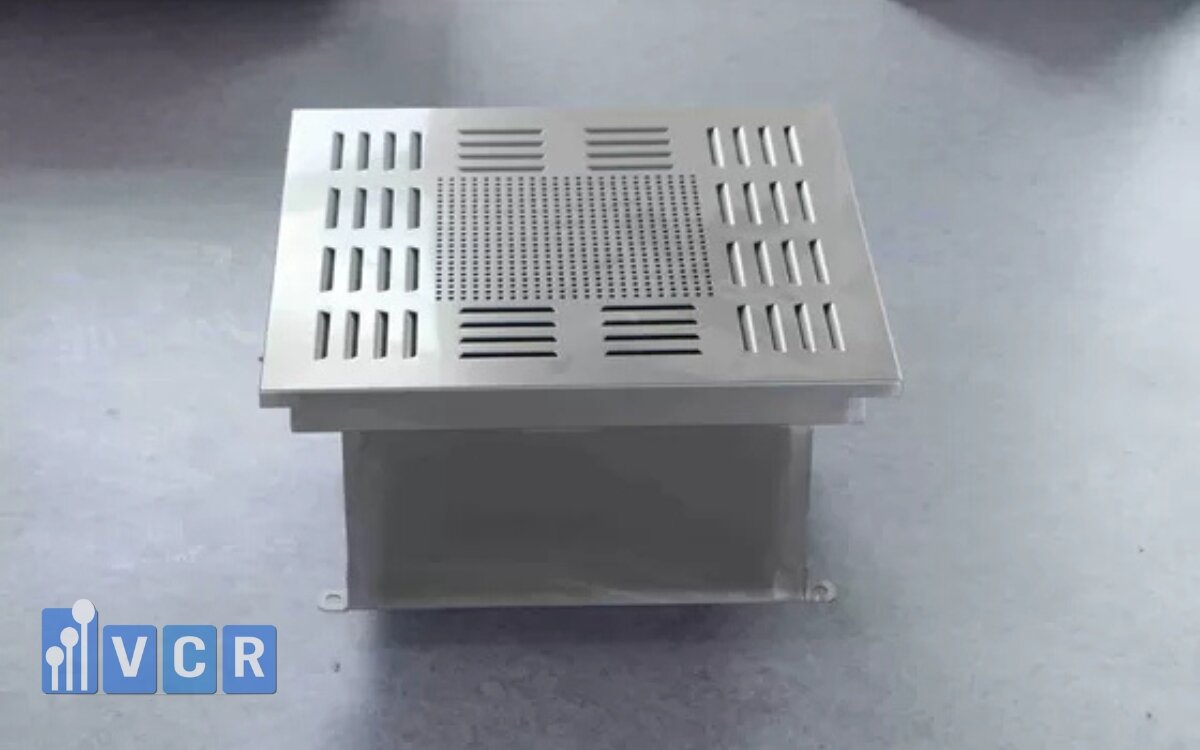

- Structure: Housing + HEPA filter + air diffuser

- Features: No built-in fan; relies on central HVAC pressure

- Application: Suitable for areas with stable air pressure, where airflow doesn’t need to be adjusted individually

- Advantages:

- Cost-effective

- Simple design and easy installation

- Low maintenance

- Used in: Support zones, cleanroom corridors (ISO 8-7)

2.2 HEPA Box with Fan (Fan Unit)

- Structure: Same as the basic HEPA Box but includes an EC/AC centrifugal fan

- Features: Operates independently or boosts airflow in local areas

- Application: Ideal for zones requiring adjustable airflow or when HVAC cannot provide sufficient pressure

- Advantages:

- Easy to control airflow

- Reduces load on the central air system

- Flexible spatial configuration

- Used in: Main production areas, testing lines, electronic component measurement rooms

2.3 Custom HEPA Terminal Box

- Structure: Custom-designed based on dimensions, airflow, and ceiling layout

- Optional Features:

- Adjustable damper

- Differential pressure gauge

- Noise-reduction panel

- Advantages:

- Optimized for real-world ceiling configurations

- Easily integrated into automated operations

- Low noise, stable airflow

- Used in: ESD testing rooms, high-precision inspection zones (ISO 5-6)

See more: HEPA Box Enclosures for Gel-Seal Filters in Pharmaceutical Cleanrooms

3. Updated HEPA Box Price List for 2025

Below is the updated price list for 3 popular types of HEPA Boxes used in electronics manufacturing facilities in Vietnam—especially in component production, SMT lines, and ESD inspection zones:

|

Product Code |

Product Name |

Material |

Common Size |

Estimated Price (VND excl. VAT) |

Key Features |

|

HB-INOX |

Stainless Steel HEPA Filter Box |

SUS 304/201 |

610x610x300 mm |

3,950,000 - 4,500,000 |

Durable, easy to clean, ideal for ISO 5-7 areas |

|

HB-LENGE |

LENGE HEPA Box - Airtight Clean Air Outlet |

Powder-coated steel + HEPA H14 |

610x610 mm or custom |

4,800,000 - 6,200,000 |

Built-in diffuser & airtight damper |

|

HB-STD |

Powder-Coated Steel HEPA Filter Box |

Powder-coated steel |

610x610 mm |

3,200,000 - 3,700,000 |

Cost-effective, suitable for ISO 7-8 zones |

Note: Prices are for reference only. Actual cost may vary depending on:

- Order quantity (bulk discount available)

- Required filtration grade (H13, H14, ULPA)

- Add-ons such as dampers, differential pressure gauges, anti-corrosion frames

4. Key Factors Affecting HEPA Box Prices

The cost of a HEPA Box varies significantly based on technical specifications and order conditions. Below are the four main factors that influence pricing:

4.1 Filtration Grade: H13, H14, or ULPA

- HEPA H13: Filters ≥ 99.95% of ≥ 0.3µm particles - common for ISO 7-8 cleanrooms

- HEPA H14: Filters ≥ 99.995% of ≥ 0.3µm particles - ideal for ISO 5-6 zones

- ULPA: Filters ≥ 99.9995% of ≥ 0.12µm particles - used in ultra-clean environments like semiconductor fabs or photonics labs

The higher the filtration grade → the higher the cost, due to stricter standards and material requirements.

4.2 Fan Integration: With or Without Fan?

- Standard HEPA Box (non-fan): Relies on the central AHU, more affordable

- Fan-integrated HEPA Box: Includes an EC/AC centrifugal fan, allows independent airflow control

Adding a fan can increase the price by 1.5-2 times, but allows better flow management per zone.

4.3 Housing Material: Powder-Coated Steel vs Stainless Steel

|

Material |

Cost |

Characteristics |

|

Powder-coated steel |

Lower |

Suitable for ISO 7-8, areas with minimal chemical exposure |

|

Stainless steel (SUS 304) |

Higher |

Corrosion-resistant, easy to clean, ideal for ISO 5-6 or chemical zones |

Stainless steel is the preferred choice in electronics factories that require high cleanliness and durability.

4.4 Order Quantity & Delivery Time

- Bulk orders often qualify for 5-15% discounts

- Rush orders (1-3 days delivery) may incur extra handling fees

- Custom-size orders will have added design costs and longer lead times

Tip: For new factory projects, order in batches to reduce cost and ensure synchronized installation timelines.

See more: The Indispensable Role of HEPA Boxes in Pharmaceutical Cleanrooms

5. Technical Notes When Installing a HEPA Box

Proper installation of a HEPA Box not only ensures effective air filtration but also extends the unit’s lifespan and helps maintain stable cleanroom pressure. Below are critical points to consider during installation:

5.1 Mounting Location on Cleanroom Ceiling Panels

- The HEPA Box should be installed on the ceiling above the main production area, where air flows directly downward onto the workspace

- The ceiling should be cleanroom-grade aluminum or panel systems, reinforced to handle the unit's weight

- There must be a clearance of at least 250-300mm above the HEPA Box for air duct connection

Avoid installing HEPA Boxes near entry doors or areas with high foot traffic, which may disturb airflow patterns.

5.2 Connecting to the Central HVAC System

- For non-fan HEPA Boxes, ensure the AHU provides adequate pressure to push air through the filter

- Use well-sealed flexible or rigid ducts, and install airflow dampers to help balance air pressure

- In multi-zone areas, it's recommended to have independent airflow control per HEPA Box or zone group

5.3 Ensuring Correct Airflow Direction

- The diffuser must always face downward

- Never install the filter in reverse: the clean air side must always be on the outlet (bottom)

- If using a differential pressure gauge, make sure it’s mounted correctly and not reversed

Improper airflow direction will compromise filtration performance and may damage the unit.

5.4 Post-Installation Leak Test and Performance Check

After installation, always:

- Check sealing at duct connections

- Measure pressure drop across the filter

- Measure airflow at the diffuser outlet

- Conduct DOP or photometer testing if required for ISO 5-6 areas

All measurements should be recorded for GMP/ISO compliance audits.

6. HEPA Box vs FFU - Which One Should You Choose?

Both HEPA Boxes and Fan Filter Units (FFUs) are terminal air filtration devices used in cleanrooms, but they differ in design, functionality, and cost. Choosing the right one depends on your cleanroom classification, HVAC design, and budget.

6.1 Side-by-Side Comparison

|

Criteria |

HEPA Box |

FFU (Fan Filter Unit) |

|

Operation |

Relies on central HVAC pressure |

Has its own fan, creates airflow |

|

Structure |

HEPA filter + housing + diffuser |

Centrifugal fan + HEPA filter + casing |

|

Airflow Control |

Depends on HVAC |

Independently adjustable |

|

Application |

Stable-pressure zones |

Zones with individualized flow control |

|

Initial Cost |

20-40% lower |

Higher (fan motor integrated) |

|

Noise Level |

Very low (no fan) |

40-55 dB (fan noise present) |

6.2 When to Use Each Device in Electronics Manufacturing

Choose HEPA Box if:

- Your HVAC system is powerful and maintains stable pressure

- You need terminal filtration for standard clean zones

- You aim to save on initial investment and power usage

- Commonly used in SMT lines, packaging areas, clean corridors

Choose FFU if:

- You need to independently control airflow per zone

- The HVAC system is insufficient in some areas

- You’re upgrading a cleanroom without redesigning the entire air system

- Ideal for clean booths, testing rooms, and ISO 5-6 precision zones

6.3 Final Recommendation

|

Requirement |

Recommended Device |

|

Lower initial cost |

HEPA Box |

|

Flexible airflow control |

FFU |

|

ISO 7-8 cleanroom |

HEPA Box |

|

ISO 5-6 cleanroom |

FFU or HEPA Box with fan |

Tip: A HEPA Box with a fan offers a balanced solution—more affordable than FFUs, while still enabling flexible airflow control.

See more: Verifying HEPA Box Performance for Cleanroom Suitability

7. Frequently Asked Questions About HEPA Boxes

1. Is a HEPA Box required for ISO 7 cleanrooms?

Yes.

An ISO Class 7 cleanroom requires control of particles to ≤ 352,000 particles/m³ (≥ 0.5µm). Therefore, a HEPA Box is a standard device to ensure terminal air reaches the required cleanliness.

You can choose a non-fan HEPA Box if the AHU provides sufficient pressure, or a fan-integrated version if the area requires localized airflow control.

2. How often should the filter in a HEPA Box be replaced?

Typically every 6-12 months.

Replacement frequency depends on:

- Usage intensity

- Cleanliness of incoming air

- Filter grade (H13/H14)

Tip: Monitor pressure drop (Pa) across the filter—if it exceeds 250-300 Pa, replacement is recommended. Plan regular inspections every 3-6 months.

3. Can a HEPA Box be used together with an FFU?

Not recommended.

An FFU already includes a HEPA filter and built-in fan, so there’s no need to add a HEPA Box.

Using both in the same area can lead to over-filtration, excess static pressure, and airflow disruption—negatively impacting system performance.

If you need higher filtration capacity, opt for a ULPA-grade FFU rather than adding an extra HEPA Box.

8. Get a Quick & Accurate HEPA Box Quotation

Are you looking for the right HEPA Box for your electronics factory, but unsure which model meets your technical needs, fits your budget, or meets your project timeline?

No worries - the VCR technical team is here to support you from start to finish:

- Expert consultation based on your actual cleanroom layout

- Quotations sent within 2 working hours

- Technical drawings and installation design support included

Contact us now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR