HEPA (High-Efficiency Particulate Air) filter terminal boxes play a critical role in safeguarding air purity within cleanrooms.

These enclosures house HEPA filters, ensuring meticulous filtration of airborne particles in various industries, particularly pharmaceuticals and electronics, where maintaining a pristine environment is paramount.

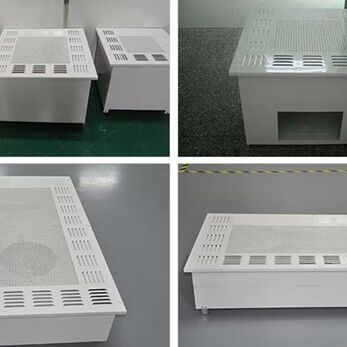

Components of a HEPA Filter Terminal Box

- Static Pressure Box: This core component forms the housing for the HEPA filter and is typically constructed from durable and corrosion-resistant materials like stainless steel.

- Diffuser Plate: Positioned downstream of the HEPA filter, the diffuser plate plays a vital role in distributing the filtered air uniformly throughout the cleanroom. Diffusers come in various shapes and styles, ensuring optimal airflow patterns tailored to specific cleanroom requirements.

- HEPA Filter: The heart of the enclosure, the HEPA filter captures airborne particles down to a specific size threshold (typically 0.3 microns) with exceptional efficiency.

- Air Intake Interface: HEPA filter terminal boxes offer flexibility in terms of air intake configuration. They can be designed with either a top-connected or side-connected air intake to accommodate diverse cleanroom layouts and airflow requirements.

See more: The Indispensable Role of HEPA Boxes in Pharmaceutical Cleanrooms

Key Characteristics of HEPA Filter Terminal Boxes

- Cleanroom Compatibility: HEPA filter terminal boxes are suitable for a wide range of cleanroom classifications, including Class 1000, Class 10,000, and Class 100,000. These classifications denote the maximum allowable airborne particle concentration within the cleanroom.

- Material Versatility: The choice of material for the HEPA box housing can vary depending on specific needs and budget considerations. Common materials include stainless steel (offering superior durability and corrosion resistance), aluminum plate (lightweight and cost-effective), carbon steel (a balance between affordability and strength), and even plastic (suitable for certain less-demanding applications).

- Airflow Management: HEPA filter terminal boxes are typically designed for turbulent airflow supply within the cleanroom ceiling. Turbulent airflow creates a mixing effect, promoting better air distribution and minimizing the risk of stagnant zones where contaminants can accumulate.

- Diffuser Design Flexibility: As mentioned earlier, diffuser plates within HEPA filter terminal boxes come in various configurations. Square, swirl, and other diffuser designs can be chosen to achieve the desired airflow pattern and ensure optimal air distribution within the cleanroom.

- Air Intake Options: The flexibility of top-mounted or side-mounted air intake connections allows for adaptation to various cleanroom layouts and ductwork configurations.

- Flange Options: HEPA filter terminal boxes typically feature square or round flange connections for seamless integration with the cleanroom's air handling system.

- Cost-Effectiveness: HEPA filter terminal boxes offer a compelling combination of functionality and affordability. Their simple construction and efficient design make them a cost-effective solution for cleanroom air filtration needs.

See more: Verifying HEPA Box Performance for Cleanroom Suitability

Conclusion

HEPA filter terminal boxes, with their versatility, efficient filtration, and cost-effective design, are a cornerstone of cleanroom air purification systems. Understanding their components, characteristics, and function empowers facility engineers and cleanroom professionals to select the most suitable configuration for their specific cleanroom environment.