HEPA Box is a terminal air filtration device used to maintain clean airflow at ISO Class 5–8 in electronics component test areas. With the ability to remove fine dust and interfering ions, a HEPA Box plays a key role in ensuring the accuracy and stability of component measurement and testing processes.

- 1. What is a HEPA Box? Why is it needed in a component test area?

- 2. Criteria for selecting a suitable HEPA Box for a component test room

- 3. Why choose a specialized HEPA Box supplier for the electronics sector?

- 4. VCR – A reliable HEPA Box provider for the electronics industry

- 5. Comparison of common HEPA Box types

- 6. Frequently Asked Questions (FAQ)

1. What is a HEPA Box? Why is it needed in a component test area?

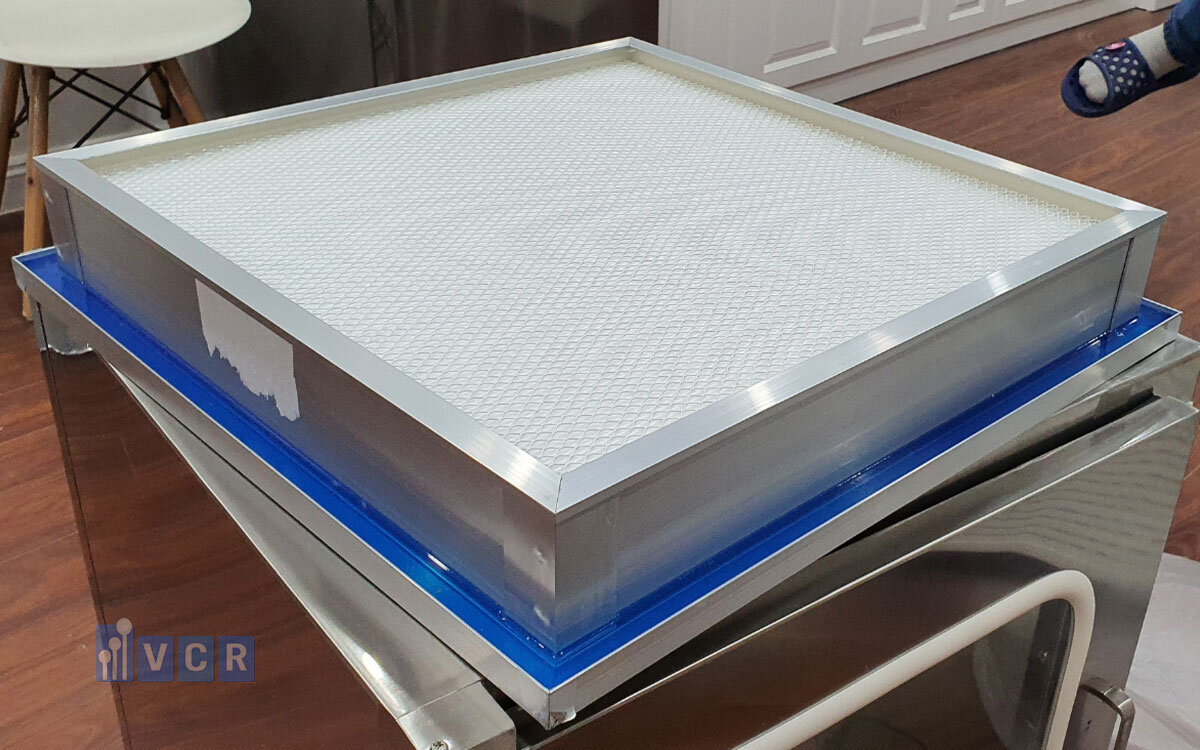

A HEPA Box is a terminal filtration device installed in a cleanroom system. Its function is to deliver clean air through an integrated HEPA (High Efficiency Particulate Air) filter. This unit is typically mounted in the ceiling or at air supply locations within the cleanroom, especially in zones requiring high cleanliness such as electronics component test areas.

The HEPA Box operates by directing air from a central HVAC or booster fan through its internal HEPA filter. At this point, ultrafine particles (≥ 0.3 micron) are captured, allowing the outgoing air to meet ISO Class 5–8 standards depending on configuration. Some HEPA Boxes also integrate a fan (then called EC or AC centrifugal fan) to boost pressure and airflow in isolated zones.

Role of controlling clean airflow in the test area

In the process of testing and evaluating electronic components (ICs, chips, circuit boards, etc.), fine dust, contaminants, or ions in the air can cause:

-

Electrical signal interference

-

Surface corrosion of components

-

Distortion in measurement results and device performance

Therefore, maintaining continuous clean airflow via a HEPA Box is crucial for ensuring the precision and reliability of the testing process.

Consequences of failure to control dust and contaminants

Without effective air filtration in a component test area:

-

The defect rate increases due to measurement errors

-

Expensive components may be damaged by static or dust adhesion

-

The credibility and testing capability with respect to OEM clients may decline

-

Costs for rework, warranty issues, and production delays will rise

Thus, a HEPA Box is not merely an auxiliary device, but an indispensable component in designing cleanrooms for the electronics industry.

Read more: Latest price list of Hepa Box used in electronics factory

2. Criteria for selecting a suitable HEPA Box for a component test room

Choosing the right HEPA Box not only ensures the quality of clean airflow but also has a direct impact on investment cost and operating efficiency. Below are five important criteria to consider:

1. Filtration efficiency (HEPA H13 / H14)

HEPA filters used in HEPA Boxes typically meet the EN1822 standard and are classified by grade:

-

H13: removes ≥ 99.95% of particles ≥ 0.3 micron

-

H14: removes ≥ 99.995% of particles ≥ 0.3 micron

For electronics test rooms — where high and stable cleanliness is required — it is recommended to favor H14 filters to ensure measurement accuracy.

2. Airflow pattern: laminar (unidirectional) vs turbulent (non-uniform)

-

Laminar flow: Clean air moves uniformly in one direction (top-to-bottom or back-to-front), minimizing cross-contamination — suited for ISO Class 5–6 zones

-

Turbulent flow: Air moves in a mixed or non-uniform pattern — suitable for areas with moderate cleanliness requirements (ISO Class 7–8)

The choice of airflow type must match the test room layout and the type of components being measured.

3. With or without built-in fan

-

HEPA Box without fan: Used when the cleanroom has a supply from a central AHU, FCU, or booster fan system. Suitable for cleanrooms designed with an existing HVAC system

-

HEPA Box with fan (EC or AC centrifugal fan): Actively generates clean airflow; ideal for standalone test zones or upgrades where modifying the main system is impractical

Depending on factory layout and investment constraints, engineers should choose a configuration that balances cost and performance.

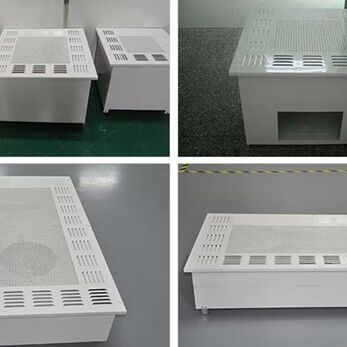

4. Casing material: stainless steel, powder-coated steel

The casing material affects durability, ease of cleaning, and corrosion resistance:

-

Stainless Steel 304: High durability, chemical resistance, easy cleaning — suitable in humid or chemical environments

-

Powder-coated steel: More cost-effective, sufficient for relatively dry or non-corrosive test areas

5. Dimensions, airflow rate, static pressure

Depending on room area and cleanliness requirements, calculations should include:

-

Filter frame sizes: commonly 600×600 mm, 610×1220 mm, etc.

-

Airflow rates: typically in the range of 500–1200 m³/h

-

Static pressure: select fans (if present) to overcome pressure drop across the filter

An effective HEPA Box is one whose specification is matched to the system and is synchronized with the cleanroom’s air handling design.

Read more: HEPA Box Installation Best Practices

3. Why choose a specialized HEPA Box supplier for the electronics sector?

Not every cleanroom equipment vendor deeply understands cleanroom HEPA Box for electronics testing areas. Choosing a specialized supplier not only helps optimize capital costs but also ensures long-term performance.

1. Deep knowledge of cleanroom requirements in electronics

The electronics industry has unique characteristics:

-

High demands for fine particle and static control

-

Air cleanliness directly influences product quality

-

Need to maintain stable environments throughout testing

A supplier specialized in electronics will understand standards (ISO 14644-1, IPC-A-610, etc.) and can advise the right devices for each cleanroom class and test process.

2. Technical consultation optimized for test room layout

Test room spaces are often limited, and airflow must be optimized without interfering with operators. A professional provider can:

-

Calculate airflow requirements based on area and class

-

Propose installation points (ceiling, walls, etc.)

-

Ensure even airflow distribution and avoid dead zones

This saves time and cost in design and construction phases.

3. Ready stock or custom design

An experienced partner will:

-

Offer off-the-shelf industrial HEPA Boxes

-

Accept custom orders in size, material, and configuration

-

Integrate with fans, pressure sensors, UV lamps if needed

This flexibility supports new builds, expansions, or retrofits.

4. On-site installation support and performance verification

HEPA Boxes not only must be installed correctly, but their performance must be verified in real operation. A reputable provider will:

-

Send technicians for installation, pressure and airflow measurement

-

Provide performance reports (e.g. DOP test, leak test)

-

Guide on maintenance and periodic filter replacement

This ensures the cleanroom system operates stably over time.

Read more: Structure and application of HEPA Box for ISO 5 clean room

4. VCR – A reliable HEPA Box provider for the electronics industry

When choosing a HEPA Box supplier for component test zones, the technical details, product quality, and implementation capability are key. VCR — with deep expertise in cleanroom equipment — is a trusted partner for many electronics factories in Vietnam.

1. VCR’s supply capabilities

VCR specializes in importing, fabricating, and distributing terminal air filtration devices such as:

-

HEPA Boxes without fans for central HVAC systems

-

HEPA Boxes with fans (EC or AC centrifugal fan) for independent test zones

-

HEPA/ULPA filters compliant with EN1822

Their engineering team can design cleanroom airflow systems and layouts for electronics, SMT, EMS facilities.

2. Diverse HEPA Box catalog

VCR offers a full lineup of HEPA Boxes:

-

Fanless HEPA Boxes in multiple sizes

-

Fan-equipped HEPA Boxes (EC or AC centrifugal fan) with airflow around 500–1200 m³/h

-

Options in stainless steel 304, powder-coated steel, or antistatic aluminum

-

Custom features: maintenance doors, differential pressure gauges, UV lamps, control modules

Clients may choose off-the-shelf models or order custom configurations.

3. Clear warranty, testing, aftersales policy

VCR commits to:

-

12–18 months warranty on devices

-

On-site testing for leaks and filtration performance (e.g. DOP testing)

-

Periodic filter replacement services

-

Operation and maintenance training for client personnel

With prompt technical support and responsive aftersales, VCR has earned high regard in precision-critical electronic projects.

Read more: Supplier of GMP‑Standard Cleanroom HEPA Box Filters

5. Comparison of common HEPA Box types

The choice of HEPA Box depends on the cleanroom’s air system, flexibility needs, and investment costs. Below is a comparison between two commonly used types in electronics test zones:

| Type | Built-in Fan? | Airflow Rate (m³/h) | Application |

|---|---|---|---|

| HEPA Box without fan | No | Depends on external fan | Cleanrooms using a central HVAC or booster air system |

| HEPA Box with fan (EC or AC centrifugal fan) | Yes | 500–1000 (or more) | Standalone test zones or retrofit areas needing independent clean airflow |

HEPA Box without fan

-

Advantages: Lower cost, easier integration with existing systems

-

Limitations: Completely reliant on external airflow; requires precise calculations of pressure and flow

HEPA Box with fan (EC or AC centrifugal fan)

-

Advantages: Self-driven clean airflow, easier installation, suitable for standalone test spaces

-

Limitations: Higher cost, requires separate power and periodic fan maintenance

Depending on usage scenario and system architecture, engineers should select the HEPA Box type that offers optimal filtration and cost efficiency.

Read more: How to test HEPA Box performance with DOP test

6. Frequently Asked Questions (FAQ)

Can HEPA Boxes be used for all types of test rooms?

Yes. HEPA Boxes can be applied to most cleanroom types and component test areas, from ISO Class 5 to Class 8. However, their effectiveness depends on proper configuration:

-

Filter efficiency (H13 / H14)

-

Suitable airflow and pressure

-

Correct mounting location and airflow direction

Correct specification is essential for optimal performance.

How often should the HEPA filter be replaced?

Typically every 6 to 12 months, depending on:

-

Input air contamination levels

-

Duration of continuous use

-

Operating environment (dusty, chemical, high humidity)

In electronics test areas, it is recommended to monitor differential pressure or perform DOP testing periodically to determine the optimal replacement time.

Does VCR support cleanliness testing after installation?

Yes. VCR offers on-site performance testing services using instruments such as:

-

Particle counters

-

DOP / aerosol leak test equipment

-

Differential pressure gauges

Results are compiled into a performance report to confirm the system meets cleanroom standards.

Need a clean airflow solution in your electronics test area? Want to select the right HEPA Box meeting cleanroom standards while optimizing cost?

Let VCR’s engineering team help you:

-

Wide selection of HEPA Boxes in stock, with fast delivery

-

Custom design services tailored to your layout

-

On-site installation, testing, and full handover

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Dat VCR