HEPA Box is essential for GMP cleanrooms in pharma, supplements, electronics, and cosmetics. Choosing the wrong supplier can compromise filtration and validation. This guide helps you select a trusted HEPA Box provider that meets GMP and system requirements.

Introduction to GMP and HEPA Box

In industries such as pharmaceuticals, electronics, cosmetics, and functional foods, maintaining a dust-free and bacteria-free environment is essential to comply with GMP (Good Manufacturing Practice) standards. A critical component in ensuring clean air quality in cleanrooms is the HEPA Box.

The HEPA Box acts as a "gatekeeper" for airflow. When air is drawn in via HVAC systems or return fans, it passes through the HEPA Box, which removes most particles, microorganisms, and fine contaminants. This ensures that only purified air enters the cleanroom, minimizing cross-contamination and ensuring product quality and safety.

Why Choose a Reputable HEPA Box Supplier?

Not all HEPA Boxes are suitable for GMP environments. Some products may lack verified filtration performance, may not be compatible with existing HVAC systems, or may come from unreliable sources. Using subpar equipment can lead to unnecessary costs, unstable operations, and failure during GMP inspections.

That’s why choosing a reputable and experienced supplier—offering verified products that integrate seamlessly with your cleanroom system—is a crucial step to ensuring your project runs smoothly and meets regulatory standards.

What is a HEPA Box? What Types Are Available?

A HEPA Box (also known as a HEPA terminal box) is installed at the final point of an HVAC system to deliver filtered air into the cleanroom. It helps maintain air cleanliness levels such as ISO 5, ISO 7, or GMP standards.

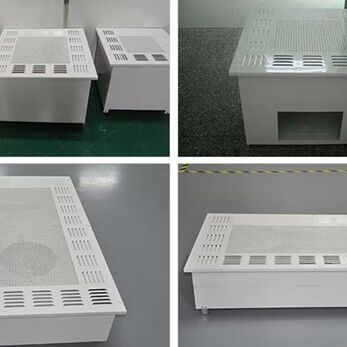

Basic Structure of a HEPA Box

-

Housing: Made from stainless steel 304/201 or powder-coated steel for durability and corrosion resistance.

-

Air Diffuser: Ensures even air distribution, reduces air velocity, and limits turbulence.

-

HEPA or ULPA Filter: The core component, with efficiency up to 99.99% for particles ≥0.3 micron.

-

Air Damper (Optional): Allows airflow control per zone; can be built-in or separate.

-

Additional Features (for premium models): Sealing gaskets, filter holding frame, and leak test ports.

Common Types of HEPA Boxes

-

HEPA Box with Plenum

-

Includes a mixing chamber above the box.

-

Suitable for stepped ceilings or pressure-controlled zones.

-

Provides stable, low-vibration airflow.

-

-

HEPA Box with Airflow Control

-

Built-in damper for zone-specific airflow regulation.

-

Energy-efficient and suitable for pressure-segregated systems.

-

-

Mini-Type Terminal HEPA Box

-

Compact size for limited-space applications.

-

Ideal for local filtration in pass boxes, biosafety cabinets, or microbiology labs.

-

Choosing the right HEPA Box enhances air filtration, optimizes HVAC efficiency, and facilitates GMP compliance.

Read more: Latest price list of HEPA BOX used in medical clean rooms

Key Criteria for Selecting a GMP-Compliant HEPA Box

For GMP-compliant cleanroom projects in pharma, food, medical devices, or electronics, consider these 4 key criteria beyond price and appearance:

-

Filtration Efficiency ≥ 99.99% @ 0.3μm

-

Required for GMP and ISO Class 5–8.

-

HEPA H13/H14 or ULPA filters are recommended for critical environments.

-

-

Safe, Easy-to-Clean Materials

-

Stainless steel 304/201 prevents corrosion and contamination.

-

Smooth surfaces allow easy cleaning, reducing microbial growth.

-

-

Certified Quality Testing (CO-CQ, DOP Test, Leak Test)

-

Must have valid manufacturer certifications and test results.

-

DOP test verifies filter performance; leak test ensures no air bypass.

-

-

Compatibility with Existing HVAC Systems

-

Standard sizing and adaptable connectors (round/square).

-

Modularity for easy maintenance without interrupting operations.

-

A fully compliant HEPA Box ensures a stable cleanroom environment, long-term efficiency, and GMP audit success.

Benefits of Choosing a Certified HEPA Box Supplier

-

Stable Operation & GMP Compliance

-

Verified efficiency, airtight seals, and high-durability materials.

-

Smooth airflow, reduced back-contamination, and easier GMP/ISO audits.

-

-

Minimized Cross-Contamination Risks

-

Antibacterial materials and high-performance filters prevent reverse contamination and maintain pressure differentials.

-

-

Comprehensive Installation Support

-

Professional suppliers offer layout consulting, on-site setup, and testing services.

-

Speeds up project timelines and prevents technical errors.

-

-

Complete Documentation

-

Includes CO (Certificate of Origin) and CQ (Certificate of Quality).

-

Also provides drawings, installation manuals, and maintenance guides for QA and validation teams.

-

Read more: Structure and application of HEPA Box for ISO 5 clean room

VCR – Trusted Supplier of GMP-Grade HEPA Boxes

With over a decade of experience, VCR specializes in cleanroom solutions for pharmaceutical, electronics, food supplement, and cosmetic sectors.

VCR’s Strengths

-

10+ years of industry expertise.

-

Products meet international standards: GMP, ISO 14644-1, CE.

-

Wide product range: plenum boxes, airflow-controlled boxes, compact models for tight spaces.

Full-Service Support

-

Tailored consultations for different industries.

-

On-site installation, airflow adjustment, and airtightness testing.

-

Post-installation DOP/leak testing with QC documentation.

Comparison Table of Popular HEPA Box Models from VCR:

| Model | Material | Filtration Efficiency | Size (mm) | Typical Application |

|---|---|---|---|---|

| HB-01 | Stainless 304 | ≥99.99% @ 0.3μm | 600 x 600 | Pharmaceutical cleanrooms |

| HB-02 | Powder-coated steel | ≥99.995% | 610 x 1220 | Electronics or semiconductor plants |

| HB-03 | Stainless 201 | ≥99.97% | Customizable | Microbiology labs, research facilities |

Recommendations:

-

For high durability and easy sanitation → Choose HB-01.

-

For larger areas and higher airflow → Go with HB-02.

-

For tight spaces or special configurations → HB-03 is ideal.

Read more: Unveiling the HEPA Box: Guardian of Clean Air in Critical Environments

Frequently Asked Questions (FAQs)

Q: Can HEPA Boxes be used in ISO 5 cleanrooms?

Yes, but use high-efficiency filters like HEPA H14 or ULPA. Ensure proper installation and perform DOP testing post-installation.

Q: How often should HEPA filters be replaced?

Typically every 6–12 months in pharma/food cleanrooms. For low-dust environments, it can last longer. Check pressure differential regularly to determine replacement timing.

Q: Does VCR provide post-installation performance testing?

Yes. VCR offers DOP and leak tests at your site, with test reports provided for GMP compliance documentation.

Need help choosing the right HEPA Box for your GMP cleanroom project?

Contact VCR for full support—from consultation to installation and testing.

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Dat VCR