HEPA Box is an important terminal air filtration device in the medical clean room system, helping to remove up to 99.99% of dust particles and microorganisms. Update the latest HEPA Box price in medical clean rooms to choose an international standard air filtration solution for hospitals, operating rooms, and ICUs.

- 1. What is a HEPA Box and why is it important in medical cleanrooms?

- 2. Factors influencing HEPA Box pricing

- 3. Updated 2025 HEPA Box price list (based on popular configurations)

- 4. When should you choose a high-end HEPA Box?

- 5. Recommendations for selecting the right HEPA Box for specific medical areas

- 6. Frequently Asked Questions about HEPA Boxes

- 7. Contact & Order Genuine HEPA Boxes

1. What is a HEPA Box and why is it important in medical cleanrooms?

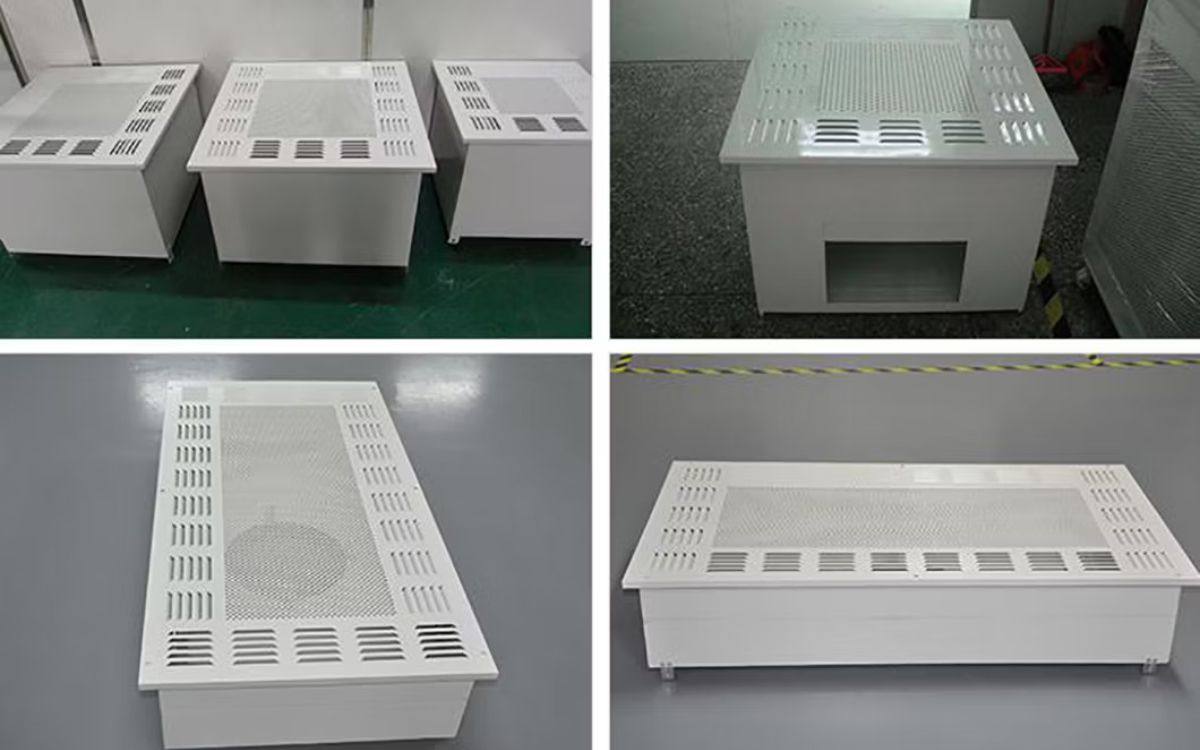

A HEPA Box is a terminal filter device installed at the end of the air supply system in a cleanroom. This device is integrated with a HEPA or ULPA filter, capable of removing up to 99.99% of airborne particles as small as 0.3 microns—ensuring sterile air quality in medical environments.

Role of the HEPA Box in terminal air filtration

- It is the final stage of air filtration before entering the clean zone

- Prevents dust, microorganisms, and harmful contaminants that may cause cross-contamination

- Maintains positive pressure and controls airflow according to cleanroom standards

In a cleanroom HVAC system, the HEPA Box acts as the "final checkpoint" to ensure air entering critical areas is properly filtered.

Applications of HEPA Box in medical areas

HEPA Boxes are typically used in areas requiring high levels of sterility, including:

- Operating rooms: Removes microorganisms to reduce the risk of post-surgical infections

- Intensive Care Units (ICU): Maintains safe air conditions for critical patients

- Drug compounding or antibiotic preparation rooms: Prevents contamination from particles or microbes

Hospitals certified under international standards (JCI, ISO 15189, etc.) are required to install HEPA Boxes in critical zones.

Standards related to HEPA Boxes: ISO & GMP

The use and installation of HEPA Boxes in medical cleanrooms must comply with the following standards:

- ISO 14644-1: Classifies cleanroom levels based on particle concentration

- GMP - WHO/EU: Requires high-efficiency filtration for sterile drug production areas

- EN 1822: Defines performance testing for HEPA/ULPA filters

To meet these standards, HEPA Boxes must be leak-tested, performance-certified periodically, and installed according to the manufacturer’s guidelines.

2. Factors influencing HEPA Box pricing

HEPA Box prices can vary significantly depending on technical specifications and additional configurations. Below are the key factors to consider when evaluating or comparing HEPA Box prices for medical cleanrooms:

Size and airflow rate (CFM or m³/h)

HEPA Boxes are available in various sizes to match the airflow requirements of clean zones. Larger sizes and higher airflow capacities result in higher costs.

- Common sizes: 600x600mm, 1175x575mm, 1220x610mm

- Airflow range: from 800 m³/h to 2000 m³/h

- Custom-designed units for higher airflow needs typically cost more

Integrated filter type: H13, H14, U15

Higher filtration efficiency leads to higher costs. Filters are classified under EN 1822:

- H13: Captures 99.95% of particles ≥ 0.3 micron (common for standard medical cleanrooms)

- H14: Captures 99.995% of particles ≥ 0.3 micron (used in operating rooms, sterile drug areas)

- U15: Captures 99.9995% of particles ≥ 0.12 micron (less common, high cost, used in ultra-clean areas)

Price differences between H13 and H14 models can be around 15-25%.

Casing material: stainless steel or powder-coated steel

The casing material affects durability and corrosion resistance:

- Powder-coated steel: more affordable, suitable for areas without high humidity

- Stainless steel 304: corrosion-resistant and easy to clean, ideal for strict medical environments, typically 20-30% more expensive

- High-end models may use stainless steel 316L, designed for pharmaceutical GMP zones, at significantly higher cost

Additional features: plenum box, duct connections, differential pressure gauge

Besides the main HEPA filter, HEPA Boxes may include technical add-ons:

- Plenum Box: stabilizes airflow before filtration

- Round or square duct connections: for HVAC system integration

- Differential pressure gauge: monitors filter loading and alerts for replacement

- Airflow damper, BMS integration, anti-leak sealing options

These features can increase the product cost by 10% to 40%, depending on the configuration.

Brand and origin: domestic vs imported

There are two main product categories:

- Locally manufactured HEPA Boxes: flexible for customization, cost-effective

- Imported HEPA Boxes: usually from Korea, Taiwan, Germany, etc., priced 30-50% higher due to logistics and certification costs

The choice depends on your budget, quality requirements, and delivery timelines.

See more: HEPA Box Enclosures for Gel-Seal Filters in Pharmaceutical Cleanrooms

3. Updated 2025 HEPA Box price list (based on popular configurations)

The following table includes reference prices for common HEPA Box models used in hospitals, clinics, and pharmaceutical facilities. Prices may vary depending on specifications and order volume.

|

Product Code |

Dimensions (LxWxH mm) |

Airflow (m³/h) |

Filter Type |

Casing Material |

Extra Features |

Price (VND) |

|

VCR-HB6060-H13 |

600 x 600 x 300 |

1000 |

H13 |

Powder-coated steel |

Round duct D250, manual damper |

4,800,000 |

|

VCR-HB6060-H14 |

600 x 600 x 300 |

1000 |

H14 |

Stainless steel 304 |

Round duct, pressure gauge |

6,800,000 |

|

VCR-HB1175x575 |

1175 x 575 x 300 |

2000 |

H14 |

Stainless steel 304 |

Damper + plenum box |

8,500,000 |

|

VCR-HB6060-Sensor |

600 x 600 x 300 |

1000 |

H14 |

Stainless steel 304 |

Pressure sensor + RS485 |

10,800,000 |

|

VCR-HB-Custom |

Custom size |

Custom |

H13-U15 |

Optional |

BMS connection, dual gasket |

9,000,000 - 15,000,000 |

Notes:

- Prices exclude VAT and installation/shipping costs

- Lead time: 3-7 working days depending on quantity

- Warranty: 12 months per manufacturer's standard

HEPA Boxes can be customized for HVAC system integration, including ceiling-mounted, wall-mounted, flush, or recessed designs per project requirements.

4. When should you choose a high-end HEPA Box?

Not all cleanroom areas require high-end HEPA Box configurations. However, in spaces that demand absolute sterility and strict air quality control, investing in a premium HEPA Box is essential to ensure safety and compliance with international standards.

Continuous air quality monitoring requirements

In healthcare facilities certified under GMP or JCI, monitoring air pressure and airflow is not just recommended but mandatory to maintain a consistent clean environment during operations.

- High-end HEPA Boxes typically come with differential pressure sensors, allowing real-time monitoring of filter status.

- These devices can connect to BMS or SCADA systems to issue alerts when filters approach saturation.

- Suitable for injectable drug, serum, and vaccine manufacturing facilities.

Areas requiring absolute sterility (ISO Class 5-6)

Standard HEPA Boxes are only suitable for ISO Class 7-8 environments. For areas classified as ISO 5-6, the filtration system must be upgraded:

- HEPA filters must meet H14 or U15 standards with strict leak testing.

- The casing should be made of stainless steel 304 or 316L to prevent particle generation.

- All airflow-contact surfaces must be seamless and fully welded to avoid secondary contamination.

Operating rooms and aseptic drug compounding areas

These zones are always considered "critical areas" where even minor air control issues can result in serious consequences like surgical infections or pharmaceutical contamination.

- High-end HEPA Boxes help establish localized clean zones.

- They are typically integrated with a plenum for airflow stabilization and a flow control damper.

- Some models can include UV lights or surgical-grade lighting fixtures.

See more: Unveiling the HEPA Box: Guardian of Clean Air in Critical Environments

5. Recommendations for selecting the right HEPA Box for specific medical areas

Selecting the appropriate HEPA Box not only ensures effective air filtration but also optimizes investment and operational costs. Below are suggested configurations for common functional areas in healthcare environments:

- Operating Room: Use HEPA Box with stainless steel 304 housing, H14 filter, and an integrated airflow damper for pressure control. Must offer high sealing, corrosion resistance, and easy cleaning.

- ICU (Intensive Care Unit): Opt for a basic HEPA Box with an H13 filter and powder-coated steel casing. A cost-effective solution sufficient for ISO Class 7-8 environments.

- Aseptic Compounding Room: Requires HEPA Box with differential pressure sensor and BMS integration for continuous monitoring. H14 or U15 filters are mandatory for these zones.

- Biologics or vaccine preparation areas: Demands high-spec HEPA Boxes, preferably with 316L stainless steel casing, seamless design, and suitable for EU-GMP Grade B or C compliance.

- Negative Pressure Room: The HEPA Box should support unidirectional airflow control to prevent leakage. Integration of a non-return valve and pressure gauge is recommended.

6. Frequently Asked Questions about HEPA Boxes

Can the HEPA filter inside a HEPA Box be replaced?

Yes. Most HEPA Box models are designed with removable frames for easy filter replacement. High-end units often include silicone gaskets to ensure leak-free and safe maintenance.

How often should HEPA filters be replaced in a HEPA Box?

- Typically, HEPA filters should be replaced every 6-12 months depending on:

- Operating hours per day

- Dust load and airborne contamination levels

- GMP or ISO inspection and testing schedules

- Using a differential pressure gauge helps determine the optimal time for replacement.

Can a HEPA Box be installed in an active medical room?

Yes, but airflow and timing must be carefully calculated to avoid disrupting room pressure or releasing particles during the process. For ICU and compounding areas, installation should be scheduled during system shutdowns or isolation periods.

Does a HEPA Box need to be paired with an FFU?

Not necessarily. A HEPA Box is a terminal filtration solution used when the central HVAC system already supplies sufficient airflow and pressure. If no HVAC system is present, an FFU (Fan Filter Unit), which combines a blower and HEPA filter, can be used instead.

See more: HEPA Filter Terminal Box: A Guardian of Clean Air in Controlled Environments

7. Contact & Order Genuine HEPA Boxes

If you're looking for HEPA Boxes that comply with GMP/ISO standards for hospitals, clinics, or pharmaceutical plants, VCR is a trusted partner with experience in hundreds of cleanroom projects nationwide.

We offer a full range of HEPA Boxes, including:

- Custom sizing options

- Genuine H13 - H14 - U15 filters

- Certified performance testing per EN1822

- Integration with sensors, BMS, airflow dampers, and pressure gauges

Order & Technical Consultation:

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR