HEPA Box is the final air filtration device in the cleanroom HVAC system, helping to remove ultra-fine dust particles before the air enters the production area. With a filtration efficiency of over 99.97%, HEPA Box is an indispensable element in the design of ISO 5 cleanrooms - where absolute air purity is required.

- 1. What is a HEPA Box?

- 2. Detailed Structure of a HEPA Box

- 3. How HEPA Box Operates in HVAC Systems

- 4. Applications of HEPA Box in ISO 5 Cleanrooms

- 5. Pros and Cons of Using HEPA Box

- 6. Frequently Asked Questions About HEPA Box in ISO 5 Cleanrooms

- 7. Need Help Choosing the Right HEPA Box for ISO 5 Cleanrooms?

1. What is a HEPA Box?

A HEPA Box is an air filtration device installed at the end of the supply air duct in a cleanroom HVAC system. Its function is to retain ultra-fine particles with sizes from 0.3 microns and above, ensuring that the air entering the cleanroom meets the required purity levels according to ISO 14644-1 standards.

In high-grade cleanroom designs such as ISO Class 5, HEPA Boxes are typically installed in the ceiling - the final point before air enters the production zone. Thanks to its high filtration efficiency (>99.97% of fine particles), the HEPA Box plays a crucial role in maintaining a high-purity air environment, particularly in pharmaceutical, microelectronics, and molecular biology applications.

Comparison between HEPA Box, FFU, and standalone HEPA filters

|

Criteria |

HEPA Box |

FFU (Fan Filter Unit) |

Standalone HEPA Filter |

|

Operation mechanism |

Passive filtration - no built-in fan |

Active filtration - includes centrifugal fan |

Accessory filter, must be installed in a housing |

|

Installation location |

End of air supply duct - ceiling mount |

Directly mounted on cleanroom ceiling |

Inside AHU or intermediate filter box |

|

Adjustability |

Adjustable with damper |

Fan speed adjustable via dimmer or PLC |

No airflow control |

|

Ideal applications |

Cleanrooms with centralized HVAC systems |

Independent cleanrooms without central HVAC |

Pre-filtration or low-grade clean zones |

|

Investment cost |

Moderate |

Higher due to integrated fan |

Low |

See more:Latest price list of Hepa box used in Cosmetic factory

2. Detailed Structure of a HEPA Box

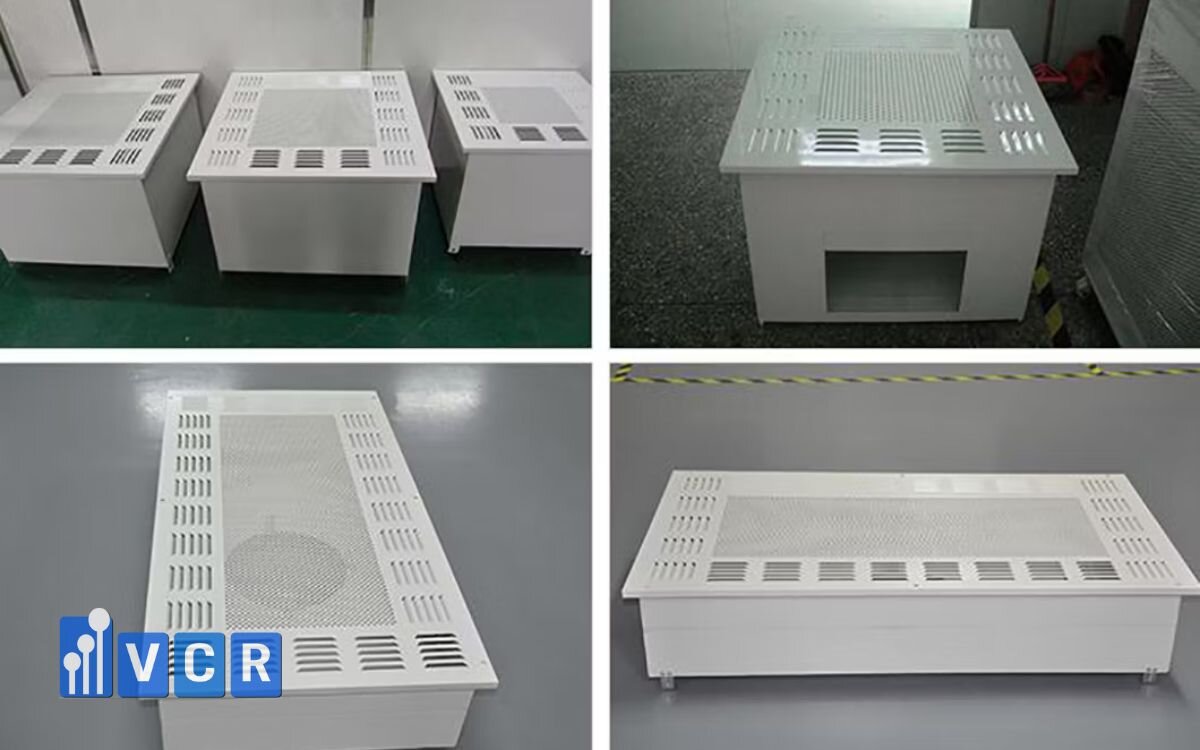

A HEPA Box has a relatively simple structure but requires precise design to ensure optimal filtration performance that meets cleanroom ISO standards. The unit is usually ceiling-mounted and connected to the supply air duct system.

Main components of a HEPA Box

|

Component |

Description |

|

Housing |

Outer casing, usually made from stainless steel 304 or powder-coated steel, resistant to corrosion and harsh cleanroom conditions. |

|

HEPA Filter |

Core component, typically uses HEPA H13 or H14 filters compliant with EN1822 standard, capable of removing >99.97% of particles ≥ 0.3 micron. |

|

Airflow Damper |

Allows adjustment of airflow and pressure, ensuring stable room conditions. Available in round or square types based on HVAC design. |

|

Filter Holding Tray |

Frame that securely holds the HEPA filter inside the box, often with removable clips for easy filter replacement. |

|

Air-Tight Gasket |

Made from soft silicone or PU, ensures leak-proof seal between the filter and the housing. |

See more: HEPA Box Installation Best Practices

3. How HEPA Box Operates in HVAC Systems

Installation position in the system

The HEPA Box is installed at the final point of the air supply duct - just before air enters the cleanroom. It is typically ceiling-mounted and connected to round or square air ducts via flange or flexible joint. This is considered the “final filtration point” in the HVAC system, where the air - already pre-treated through AHU and coarse/intermediate filters - is polished before entering the cleanroom.

Filtration mechanism of the HEPA Box

Inside the HEPA Box is a HEPA H13 or H14 filter, capable of capturing 99.97-99.995% of fine particles ≥ 0.3 microns. Air flows vertically through the filter in a unidirectional pattern.

Filtration is based on three physical mechanisms:

- Interception: captures large particles that collide with the filter fibers.

- Inertial impaction: traps smaller particles that deviate from the airstream due to inertia.

- Diffusion: captures ultrafine particles through random motion.

Role in maintaining ISO 5 cleanroom standards

To meet ISO Class 5 standards under ISO 14644-1, the particle count must be extremely low (≤ 3520 particles ≥0.5µm/m³). To maintain this level of cleanliness, the air supply system must ensure:

- Continuous clean air flow through the HEPA filter

- Stable air velocity from 0.3-0.5 m/s

- Creation of a laminar (unidirectional) airflow from ceiling to floor to push particles and contaminants toward the return system

Therefore, the HEPA Box is not only a “final filter” but also plays a key role in shaping the airflow, helping establish a stable laminar flow that removes contaminants generated by personnel and equipment.

4. Applications of HEPA Box in ISO 5 Cleanrooms

ISO 5 cleanrooms (equivalent to Grade A in EU GMP) require strict control over airborne particles and microorganisms. Due to its high filtration efficiency and passive operation, the HEPA Box is widely used in critical areas of pharmaceutical, cosmetics, and electronics manufacturing facilities.

Common Areas Where HEPA Boxes Are Used

|

Application Area |

Purpose |

|

Raw material weighing rooms |

Maintain ultra-clean environment where active ingredients are handled |

|

Filling and packaging zones |

Prevent product contamination from airborne particles or microbes |

|

Clean Bench / LAF units |

Provide unidirectional clean airflow at the point of operation |

|

Sensitive sample storage rooms |

Ensure stable microclimate and localized cleanliness |

HEPA Boxes can be equipped with diffusers or upgraded to ULPA filters for stricter cleanroom classifications.

Comparison: HEPA Box vs. FFU in ISO 5 Cleanrooms

|

Criteria |

HEPA Box |

FFU (Fan Filter Unit) |

|

Operation mechanism |

Passive filtration, uses HVAC system pressure |

Active filtration, integrated fan |

|

Airflow control |

Adjustable via damper |

Flexible control via dimmer or PLC |

|

Power consumption |

No electricity required |

Requires electricity |

|

Ideal application |

Areas with strong central HVAC |

Independent, zone-based airflow control |

|

Investment & maintenance cost |

Lower than FFU |

Higher but allows more precise control |

Summary Table: Application - Reason - Technical Requirements

|

ISO 5 Area |

Reason to Use HEPA Box |

Technical Conditions to Note |

|

Pharmaceutical weighing room |

Stable, non-vibrating clean airflow |

Air velocity 0.45 ± 0.05 m/s, pressure ≥ 100 Pa |

|

Vaccine filling room |

Laminar flow to protect products |

Add diffuser if needed |

|

LAF / Electronics clean bench |

Point-of-use clean airflow |

Install HEPA Box directly above the workspace |

5. Pros and Cons of Using HEPA Box

Key Advantages

Cost-effective

HEPA Box is significantly less expensive compared to FFUs with integrated fans, making it a cost-effective solution for cleanrooms with strong centralized HVAC systems.

Easy maintenance and filter replacement

Its simple structure allows for quick and convenient filter removal and replacement. Without electrical components or fans, maintenance is minimal and straightforward.

No power consumption

Since it does not include a fan, the HEPA Box requires no electricity, reducing operational costs and eliminating electrical risk.

Important Drawbacks

Fully dependent on HVAC system pressure

Unlike FFUs, HEPA Boxes rely entirely on the pressure from the HVAC system. If airflow is insufficient, the filtration efficiency drops significantly.

Limited airflow control

Without electronic control, airflow can only be manually adjusted via damper. This makes it difficult to maintain precise air velocity (0.45 ± 0.05 m/s), which is critical for ISO 5 cleanrooms.

Quick Comparison: Is a HEPA Box Suitable?

|

Evaluation Criteria |

Is HEPA Box Suitable? |

|

Existing HVAC system with strong pressure |

Highly suitable |

|

Need for independent airflow control |

FFU is the better option |

|

Priority on cost and energy savings |

HEPA Box is optimal |

|

Cleanroom requiring precise air velocity |

Requires careful design validation |

See more:Unveiling the HEPA Box: Guardian of Clean Air in Critical Environments

6. Frequently Asked Questions About HEPA Box in ISO 5 Cleanrooms

1. How is a HEPA Box different from an FFU in actual use?

A HEPA Box is a passive filter with no fan, operating based on HVAC system pressure. An FFU includes a built-in fan, enabling it to operate independently with adjustable airflow. FFUs are recommended if the HVAC system is not strong enough.

2. Is a HEPA Box mandatory for ISO 5 cleanrooms?

Not mandatory, but it is a commonly used and effective final filtration solution in HVAC systems for ISO 5 cleanrooms—provided that airflow and design meet technical specifications.

3. Can a HEPA Box be used in ISO 4 or higher-grade cleanrooms?

Yes, but it requires an upgrade to ULPA filters and strict control of airflow. For ISO 4 or ISO 3 environments, FFUs are generally preferred for more accurate airflow control.

4. Can HEPA Boxes be installed in small cleanrooms without HVAC systems?

Not recommended. HEPA Boxes require upstream air pressure from the HVAC system to function. In cleanrooms without HVAC, FFUs with integrated fans should be used instead.

5. How often should HEPA filters be replaced?

Typically every 6-12 months, depending on usage. Differential pressure readings across the filter can help determine the right time for replacement.

7. Need Help Choosing the Right HEPA Box for ISO 5 Cleanrooms?

Whether it's for a pharmaceutical weighing room, a vaccine filling area, or a clean bench in an electronics factory, choosing the right HEPA Box from the start helps you:

- Ensure compliance with ISO 14644 cleanroom standards

- Save on long-term maintenance and operating costs

- Avoid GMP audit failures and product contamination risks

Let VCR’s technical team help you design, select, and deliver the best air filtration solution for your facility.

Contact us for a free consultation:

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR