The pharmaceutical industry relies heavily on meticulously controlled environments known as cleanrooms. These spaces safeguard product sterility by minimizing airborne contaminants like particles and microorganisms.

Here's where HEPA (High-Efficiency Particulate Air) boxes emerge as a critical technology.

Guardians of Air Purity: HEPA Boxes in Action

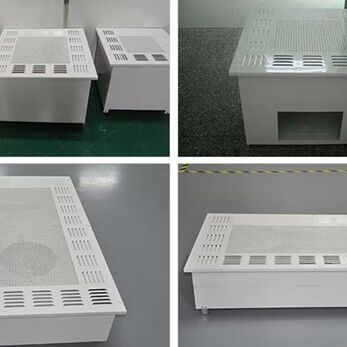

HEPA boxes serve as specialized enclosures for HEPA filters. They channel airflow through the filter media, ensuring optimal performance and preventing unfiltered air from compromising the cleanroom environment. Stainless steel is a common material choice for these enclosures due to its durability and corrosion resistance – essential qualities for cleanroom applications.

See more: Unveiling the HEPA Box: Guardian of Clean Air in Critical Environments

Beyond the Basics: Requirements for Pharmaceutical HEPA Boxes

While HEPA boxes used in conventional electronics factories may suffice for basic dust control, pharmaceutical applications necessitate stricter standards as outlined in Good Manufacturing Practices (GMP). Here's a breakdown of key requirements for HEPA boxes in pharmaceutical cleanrooms:

- Construction: The static pressure box and casing are typically fabricated from high-quality stainless steel for enhanced durability and resistance to corrosion often found in these environments.

- Airflow Management: The air supply port is equipped with a ventilation surface to ensure optimal airflow distribution within the cleanroom.

- Monolithic Structure: A key differentiator – the HEPA filter and the static pressure box function as a single, unified structure. This design minimizes potential leak paths.

- Control and Efficiency: The inlet connected to the duct system features a control valve for regulating airflow, ensuring efficient operation.

- DOP (Dioctylphthalate) Integration: For crucial leak testing, pharmaceutical HEPA boxes often incorporate DOP integration. This allows for on-site verification of gasket, frame, and filter material integrity after installation and during routine maintenance.

See more: HEPA Filter Terminal Box Controlled Environments

Why Gel-Seal HEPA Boxes Excel in Pharma

There are two primary methods for sealing HEPA filters within their housings: gasket and gel-seal. Pharmaceutical cleanrooms, with their stringent air purity demands, often utilize gel-seal HEPA boxes. These enclosures incorporate a specialized gel sealant along designated channels, forming an exceptionally tight and secure barrier around the filter edges. This superior sealing characteristic is paramount in pharmaceutical settings where even the slightest air quality breach can have significant consequences.

See more: HEPA Box Installation Best Practices

Conclusion

HEPA boxes with gel-seal technology offer an unparalleled solution for pharmaceutical cleanrooms. By understanding their design principles, specific requirements, and the importance of DOP integration, facility engineers and cleanroom professionals can ensure the highest level of air purity, safeguarding product integrity and meeting the stringent regulations of the pharmaceutical industry.