Hepa Box is an advanced air filtration solution, ensuring clean air flow that meets strict hygiene standards in food factories. With high filtration efficiency ≥ 99.97% (H13) or ≥ 99.995% (H14), the device effectively removes fine dust, microorganisms and impurities, protecting product quality.

- 1. Brief Introduction to HEPA Box and Its Application in the Food Industry

- 2. Factors Affecting the Price of HEPA Box in Food Factories

- 3. Latest Reference Price List for HEPA Box in Food Factories

- 4. Criteria for Selecting a Suitable HEPA Box for Food Factories

- 5. HEPA Box Ordering Process and Delivery Time

- 6. FAQ - Frequently Asked Questions

- 7. Contact for Latest HEPA Box Pricing

1. Brief Introduction to HEPA Box and Its Application in the Food Industry

1.1 Definition of HEPA Box

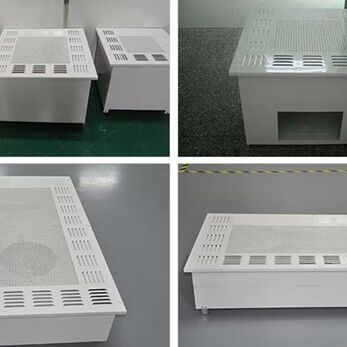

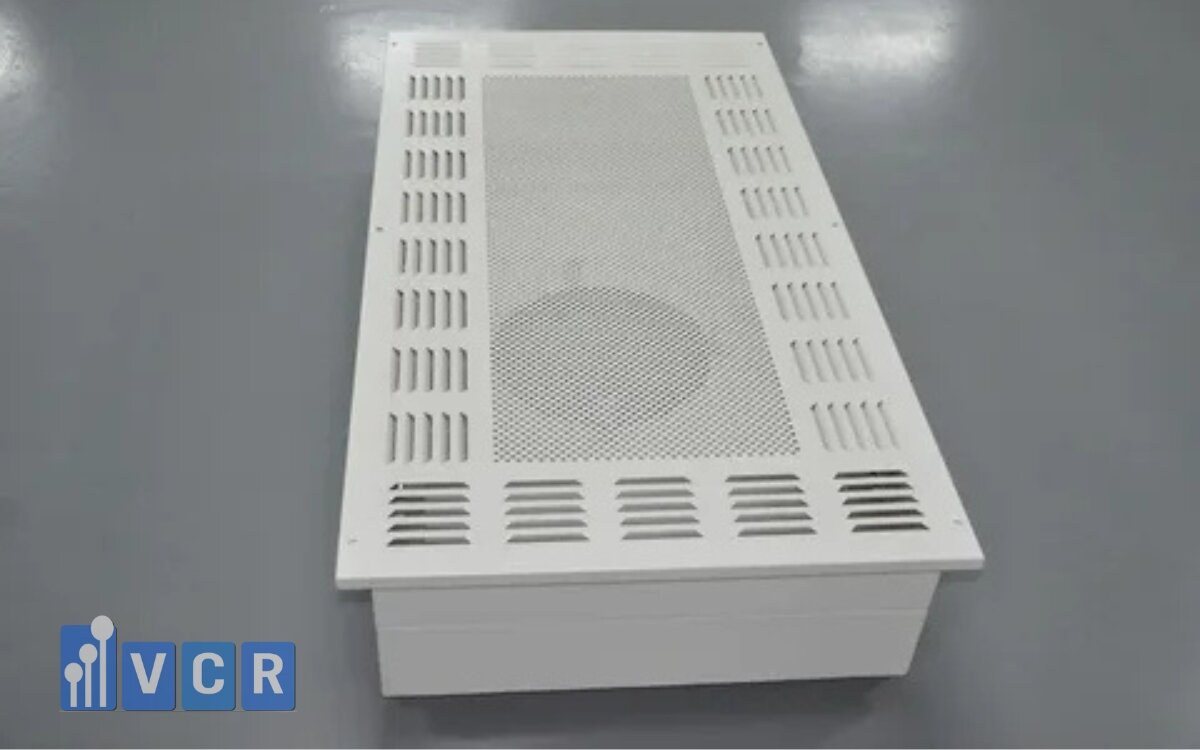

A HEPA Box is a clean air distribution device equipped with a HEPA (High Efficiency Particulate Air) filter, installed at the final air supply points in a cleanroom system. This device removes fine dust, microorganisms, and contaminants with a particle size of 0.3 microns or larger, with a filtration efficiency of ≥ 99.97% (H13) or ≥ 99.995% (H14).

In food factories, HEPA Boxes are typically installed on ceilings or walls in production, packaging, or processing areas to ensure the supplied air is always clean and meets the highest hygiene standards.

1.2 Role of HEPA Box in Ensuring Food Safety and Hygiene

- Preventing airborne contamination: Eliminates dust particles, mold, and bacteria from the supplied air in production areas.

- Maintaining a stable cleanliness level: Keeps dust and microbial concentration within permissible limits required for food processing areas.

- Protecting product quality: Reduces cross-contamination risks, extends product shelf life.

- Optimizing HVAC performance: Designed to distribute air evenly and minimize turbulence that can cause dust accumulation.

1.3 Relevant Standards

When using HEPA Boxes in food factories, the following standards should be met:

- ISO 14644 - International standard for classification and control of cleanroom cleanliness levels.

- HACCP (Hazard Analysis and Critical Control Points): A food safety management system requiring air quality control in production areas.

- Food GMP (Good Manufacturing Practice): Regulations on good manufacturing practices, including air filtration systems, clean air supply, and contamination control.

2. Factors Affecting the Price of HEPA Box in Food Factories

The price of a HEPA Box depends not only on the brand or supplier but also on various technical and usage requirements. Key factors include:

2.1 Size and Airflow (CFM)

- Size: Larger HEPA Boxes require more materials and production time, leading to higher costs.

- Airflow (CFM): Higher airflow requires larger fans and filters to ensure proper air velocity.

- Food application: Main processing areas often require higher airflow to maintain a stable cleanliness level.

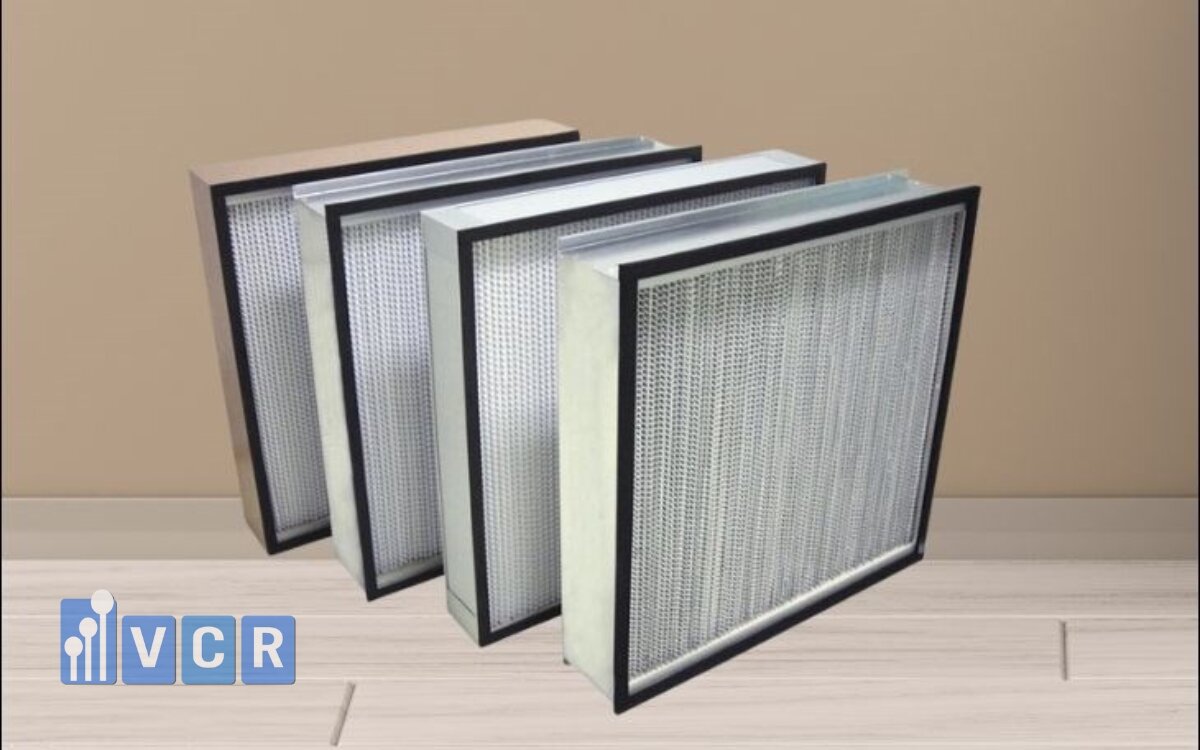

2.2 HEPA Filter Grade (H13, H14) and Efficiency

- H13: Efficiency ≥ 99.97% for particles ≥ 0.3 microns.

- H14: Efficiency ≥ 99.995% for particles ≥ 0.3 microns, suitable for areas with strict hygiene requirements.

- Note: Higher filter grades increase both filter and HEPA Box prices.

2.3 Construction Materials

- Powder-coated steel: Cost-effective, basic rust protection, suitable for dry environments.

- Stainless Steel 304: Good corrosion resistance, easy to clean, commonly used in the food industry.

- Stainless Steel 316L: Superior corrosion resistance, withstands chemicals and humid environments, highest cost.

2.4 Integrated Fan Type (if any) and Power

- Non-fan HEPA Box: Lower cost, usually connected to a central air supply system.

- HEPA Box with fan (integrated FFU): Provides independent clean air supply, not entirely dependent on HVAC systems, but more expensive due to added motor, speed controller, and soundproofing.

2.5 Additional Options

- Differential pressure gauge: Monitors filter condition and replacement time.

- UV lamp: Disinfects air, reducing microbial contamination.

- Noise reducer: Lowers noise levels during air supply, important for long-term working environments.

See more: Verifying HEPA Box Performance for Cleanroom Suitability

3. Latest Reference Price List for HEPA Box in Food Factories

|

HEPA Box Type |

Dimensions (mm) |

Airflow (CFM) |

Filter Grade |

Material |

Price Range (VND) |

|

Standard HEPA Box |

600 × 600 × 400 |

500 |

H13 |

Powder-coated steel |

7,500,000 - 9,000,000 |

|

Stainless Steel 304 |

600 × 600 × 400 |

500 |

H14 |

Stainless Steel 304 |

9,500,000 - 12,000,000 |

|

Stainless Steel 316L |

600 × 600 × 500 |

800 |

H14 |

Stainless Steel 316L |

14,000,000 - 18,000,000 |

|

With fan (FFU type) |

1175 × 575 × 400 |

1000 |

H14 |

Steel / SS 304 |

12,000,000 - 16,000,000 |

Note: Prices exclude VAT and shipping/installation costs.

4. Criteria for Selecting a Suitable HEPA Box for Food Factories

4.1 Cleanliness Level Required for Each Production Area

- Direct processing/packaging areas: Usually require H14 filter grade to remove maximum fine dust and microbes.

- Pre-processing or storage areas: May use H13 filters if hygiene requirements are less strict.

- According to ISO 14644 & HACCP: Each cleanliness class specifies maximum particle counts, guiding HEPA Box selection.

4.2 Initial Investment and Maintenance Costs

- Initial investment: Balance technical requirements with budget. SS316L or fan-integrated models cost more but last longer.

- Maintenance costs: Includes periodic filter replacement (12-18 months), pressure gauge checks, surface cleaning. Easier maintenance reduces long-term costs.

4.3 Corrosion and Moisture Resistance Requirements

- Humid or wet areas: Use SS304 or SS316L to avoid rust.

- Areas exposed to harsh cleaning chemicals: SS316L is optimal.

- Dry environments with limited budget: Powder-coated steel can be used to save costs.

4.4 Ease of Filter Replacement

- Easy frame removal design: Shortens maintenance time, reduces contamination risk.

- Airtight sealing gaskets: Prevent leakage of dirty air during replacement.

- Integrated differential pressure gauge: Ensures timely filter replacement.

See more: HEPA Box Enclosures for Gel-Seal Filters in Pharmaceutical Cleanrooms

5. HEPA Box Ordering Process and Delivery Time

5.1 Site Survey and Technical Consultation

- On-site measurement and assessment of airflow, cleanliness level, and environment.

- Requirement analysis based on ISO 14644, HACCP, or Food GMP standards.

- Material, filter grade, and accessory recommendations.

5.2 Quotation and Contract Signing

- Detailed quotation including equipment, accessories, shipping, and installation costs.

- Agreement on production time, payment terms, and warranty policy.

- Finalizing technical specifications and placing the order.

5.3 Production and Quality Inspection

- Fabrication of frame, installation of HEPA filter, accessories, and surface finishing.

- Quality tests for airflow, airtightness, filtration efficiency, noise, and electrical safety.

- Standard packaging to protect HEPA filters during transport.

5.4 Delivery and Installation

- Delivery to site with proper handling to prevent vibration or moisture damage.

- Installation, alignment, and operational checks by technical staff.

- Handover with operation and maintenance instructions.

Delivery Time:

- Stock items: 3-5 working days.

- Custom orders: 10-20 days depending on quantity and complexity.

6. FAQ - Frequently Asked Questions

Q1: How often should HEPA filters be replaced in a HEPA Box?

A1: Normally every 12-18 months, depending on usage frequency and environmental contamination level. Areas with high dust or microbial load should monitor the pressure gauge regularly for timely replacement.

Q2: Can a HEPA Box be used in a candy packaging area?

A2: Yes, provided airflow and cleanliness meet HACCP and Food GMP standards. H14 filters are recommended to minimize microbial contamination risks.

Q3: Can a HEPA Box be custom-made to specific dimensions?

A3: Yes. VCR manufactures HEPA Boxes to custom sizes, materials, and filter grades, ideal for existing systems or limited spaces.

7. Contact for Latest HEPA Box Pricing

Looking for a high-quality HEPA Box for your food factory that meets ISO 14644, HACCP, and Food GMP standards?

Let VCR support you from technical consultation, design, and manufacturing to installation - ensuring clean, safe airflow with cost optimization.

VCR Commitment:

- International-standard products, 100% quality checked before delivery.

- Genuine warranty with on-site technical support.

- Solutions tailored to budget and production needs.

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR