HEPA Box for the food industry is a terminal device that helps distribute clean air through HEPA filters, removing fine dust and microorganisms in the production area. By maintaining a clean and stable environment, HEPA Box contributes to helping businesses meet HACCP, ISO 22000 and FSSC 22000 standards.

- 1. What is a HEPA Box and its role in the food industry

- 2. What does HACCP require regarding air filtration and clean environments?

- 3. What conditions must a HEPA Box meet to comply with HACCP?

- 4. Where should HEPA Boxes be installed in food factories?

- 5. Comparing HEPA Boxes and FFUs in the food industry

- 6. Frequently Asked Questions About HEPA Boxes in the Food Industry

- 7. Need Help Choosing a HACCP-Compliant HEPA Box?

In the context of modern food production, maintaining a clean air environment is a prerequisite to ensure hygiene and compliance with standards such as HACCP. HEPA Box solutions for the food industry have become the top choice, as they are capable of removing fine dust, bacteria and impurities in the air with high efficiency, contributing to preventing cross-contamination and protecting product quality. This HEPA Box product not only helps businesses meet strict GMP and ISO requirements, but also optimizes HVAC systems to provide a stable flow of purified air. In this article, we will explore in detail how to choose the right HEPA Box for a food factory, important technical parameters and performance testing methods to ensure HACCP compliance, while improving productivity and product safety.

1. What is a HEPA Box and its role in the food industry

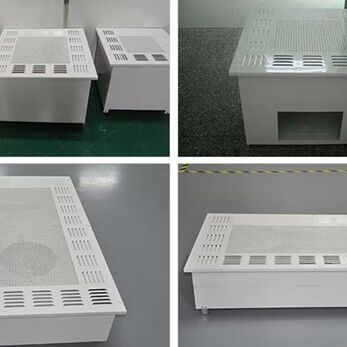

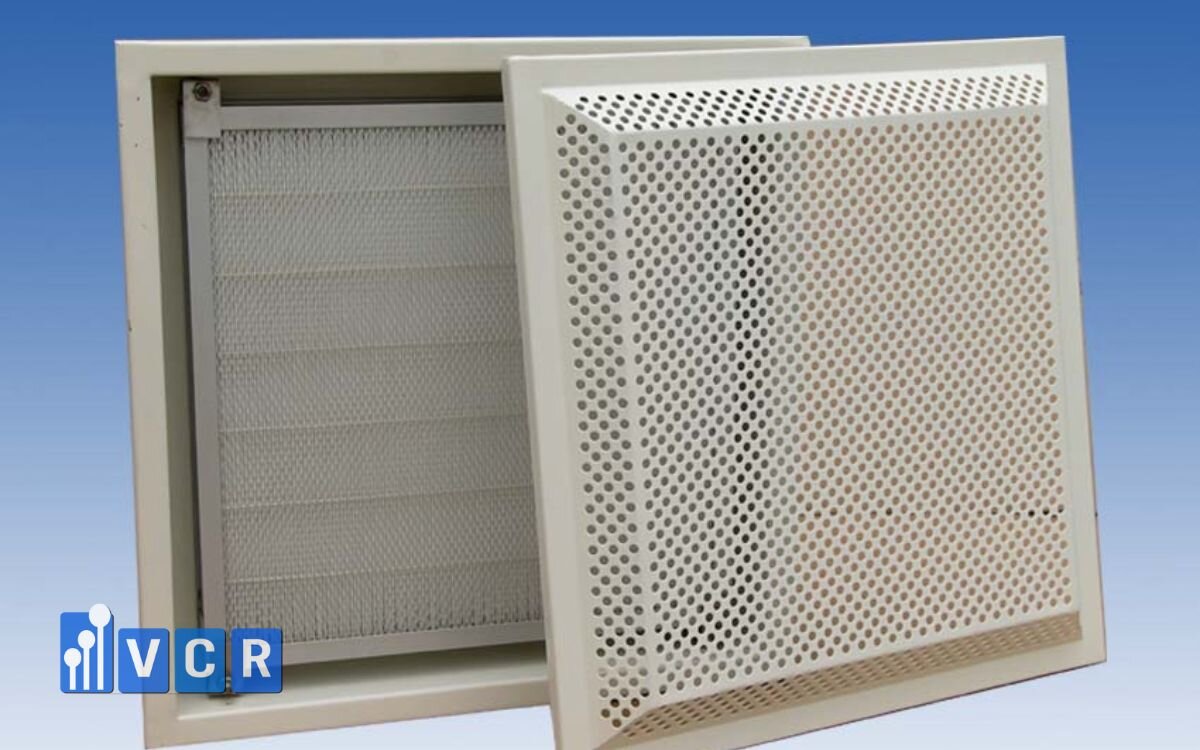

A HEPA Box is a terminal device in the cleanroom air filtration system, used to distribute air that has passed through a HEPA filter into the production area. It is usually ceiling-mounted or directly connected to the air duct system, ensuring that clean air is evenly distributed, stable, and at the required cleanliness level.

How a HEPA Box works

A HEPA Box operates on a simple mechanism:

- Air that has already passed through pre-filters and medium filters is directed through ducts to the HEPA Box.

- Inside the unit, the air is filtered one final time through a HEPA (High Efficiency Particulate Air) filter with an efficiency of ≥99.97% at 0.3 microns.

- The clean air is then evenly distributed through a diffuser panel, maintaining a stable environment in terms of cleanliness, pressure, and airflow.

The role of HEPA Box in food factories

In the food industry, air quality directly affects product safety and compliance with HACCP standards. The HEPA Box plays an essential role in:

- Controlling airborne microorganisms: Prevents the entry and spread of bacteria, mold, and spores, especially in final processing areas.

- Removing fine dust and airborne particles: Reduces contamination risks from dust, debris, or microfibers commonly found in food processing environments.

- Minimizing odors and airborne pollutants: Can be integrated with an activated carbon layer to remove odors from spices or volatile raw materials.

By using HEPA Boxes, food manufacturers can maintain a compliant clean zone, reduce cross-contamination risks, and improve their ability to pass HACCP, ISO 22000, or FSSC 22000 audits.

2. What does HACCP require regarding air filtration and clean environments?

HACCP (Hazard Analysis and Critical Control Points) is a globally recognized food safety management system. Although it does not explicitly list “HEPA Box” as a mandatory device, HACCP clearly defines principles for hazard control—where clean air management plays a critical role.

Controlling biological hazards in the air

During food processing, especially during packaging or final handling, air can carry harmful microorganisms such as bacteria, yeast, and spores. HACCP requires companies to:

- Identify potential contamination points from airborne sources.

- Implement measures to prevent the spread of microorganisms, particularly in high-risk areas handling fresh or perishable foods.

→ HEPA Boxes effectively remove airborne microorganisms before the air enters the production zone.

Preventing cross-contamination between zones

Cross-contamination is one of the most serious hazards in food manufacturing. Air can carry dust, powder, or microorganisms from one area to another if not properly controlled.

- HACCP requires clear zoning and proper airflow direction to avoid backflow.

- Practical solution: Install HEPA Boxes at transition points between clean and non-clean areas to prevent contaminated air from entering.

Requirements for unidirectional airflow and positive pressure

According to supporting standards such as ISO 14644 and Codex Alimentarius (referenced by HACCP):

- Air in clean processing areas must be supplied in a unidirectional flow.

- Main production zones must maintain positive pressure relative to surrounding areas to prevent contaminated air ingress.

→ HEPA Boxes, when integrated into the air supply system, help maintain stable positive pressure and ensure air always moves from clean to less-clean areas.

Audit references and relevant standards

- Codex CAC/RCP 1-1969 (Rev.4): Recommends the use of air filtration equipment in high-risk food handling areas.

- ISO 22000:2018, clause 8.5.4.3: Requires environmental control, including air quality.

- Real-world HACCP audit checklists (from BRCGS, FSSC, etc.) include criteria such as “air filtration” and “airflow validation.”

See more: HEPA Box and common errors during installation

3. What conditions must a HEPA Box meet to comply with HACCP?

Although HACCP does not specify mandatory equipment, to meet clean environment and biological hazard control requirements, a HEPA Box used in food processing must satisfy the following technical criteria:

|

Criterion |

HACCP Requirement |

How the HEPA Box Meets It |

|

Filtration level |

Removes microorganisms and fine particles; ensures high-quality air |

Uses HEPA H13 or H14 filter with ≥99.97% efficiency at 0.3 microns |

|

Material construction |

Smooth surface, non-dust-retaining, resistant to cleaning agents |

Made from stainless steel (Inox 304/316), fully welded, rounded edges, no dead corners |

|

Ease of maintenance and monitoring |

Allows for regular inspection and maintenance |

Equipped with a differential pressure gauge, inspection hatch, and removable filter frame |

|

Uniform airflow distribution |

Prevents backflow, dead zones, and cross-contamination |

Integrated honeycomb or perforated diffuser for balanced air distribution |

Why these factors matter

- High filtration efficiency removes airborne microorganisms often missed by surface-only controls.

- Stainless steel (304/316) construction ensures hygiene and durability under rigorous cleaning procedures.

- Easy maintenance and monitoring allow stable filtration performance and smoother audit readiness.

- Uniform airflow prevents “microbial dead zones” where bacteria can accumulate due to stagnant air.

HEPA Boxes are therefore not just filtration devices but a core component in the HACCP-based environmental control system, helping facilities meet international audit standards such as BRCGS, ISO 22000, and FSSC 22000.

4. Where should HEPA Boxes be installed in food factories?

Proper placement of HEPA Boxes in food production facilities not only ensures air quality but also meets hazard prevention requirements under HACCP and ISO 22000. The following are four key areas where HEPA Boxes should be prioritized:

1. Main Processing Room

This area involves prolonged product exposure to the environment, where microbiological agents, fine dust, and foreign matter may seriously affect quality. HEPA Boxes help:

- Provide ISO Class 7-8 clean air (depending on product requirements)

- Maintain positive pressure compared to corridors or adjacent rooms

- Reduce the risk of cross-contamination between production lines

2. Final Packaging Area

Packaging is the final step before sealing the product. Any contamination at this stage can compromise the entire batch. Installing HEPA Boxes here will:

- Keep the packaging zone under clean air control

- Limit risks from packaging dust, labels, or emissions from machinery

- Improve the likelihood of passing audits under standards like BRCGS or advanced HACCP

3. Ingredient Weighing or Mixing Rooms

These high-risk areas often handle ingredients that generate fine dust, microbial spores, or strong odors (e.g., spices or additives). HEPA Boxes help:

- Filter air before it contacts raw ingredients

- Prevent dust migration to other zones

- Fulfill physical and biological hazard control per HACCP

4. Airlocks and High-Level Changing Rooms

Transition zones between clean and non-clean areas are vulnerable to reverse airflow, bringing in microbes, dust, and odors. HEPA Boxes are used to:

- Maintain positive pressure and ensure unidirectional airflow

- Prevent contamination during door opening cycles

- Enhance performance when combined with Air Showers, interlocks, or pre-filtration systems

See more: How to test HEPA Box performance with DOP test

5. Comparing HEPA Boxes and FFUs in the food industry

Both HEPA Boxes and FFUs (Fan Filter Units) are end-point air filtration devices widely used in food factories, especially in zones requiring control over microbes and particulates. However, each device differs in structure, operating principle, and application.

When to use a HEPA Box vs. FFU?

|

Use Case |

Best Option |

Reason |

|

Central HVAC system available |

HEPA Box |

Energy-efficient; uses AHU pressure; no built-in fan required |

|

No ducting or needs independent air supply |

FFU |

Comes with integrated fan; operates independently of HVAC |

|

Requires high cleanliness (ISO 5-6) |

FFU |

Provides stable, high-volume airflow with better control |

|

Small, flexible installation areas |

FFU |

Easy to mount in ceilings or standalone locations |

|

Integrated pressure control needed |

HEPA Box |

Allows efficient pressure zoning and control in clean areas |

Pros and Cons of Each Type

|

Criteria |

HEPA Box |

FFU (Fan Filter Unit) |

|

Structure |

HEPA filter + diffuser (no fan) |

HEPA filter + built-in fan |

|

Air supply source |

Requires AHU or central ducting |

Plugs in and works independently |

|

Filtration efficiency |

High (H13-H14); depends on HVAC pressure |

High and stable airflow thanks to variable-speed fan |

|

Installation & operation |

Must integrate with HVAC design |

Flexible; suitable for retrofits or isolated zones |

|

Cost |

Lower if HVAC is already available |

Higher due to integrated fan and power requirements |

|

Maintenance |

Simpler; mainly filter replacement and pressure check |

Requires fan and filter upkeep; higher long-term cost |

Practical Usage Recommendations

- Large food factories with existing HVAC → use HEPA Boxes

- Upgraded or add-on filtration points → choose FFUs

- Zones needing independent air delivery (e.g., weighing rooms, microbiological test areas) → FFUs are more flexible

6. Frequently Asked Questions About HEPA Boxes in the Food Industry

1. Is a HEPA Box mandatory in food factories?

No. HEPA Boxes are not legally required in every food facility. However, in high-risk areas (e.g., final packaging, refined processing zones), they are considered a standard solution for meeting airborne hazard control in HACCP systems.

2. Can HEPA Boxes be installed in washing rooms or raw material storage?

Not recommended. Areas like washing zones or raw ingredient warehouses often have high humidity, dust, or uncontrolled contaminants. HEPA Boxes won’t perform effectively and may clog quickly. They are best suited for refined processing zones, clean packaging rooms, or airlocks.

3. Should I choose a stainless steel or powder-coated HEPA Box?

For the food industry, Inox 304 or 316 stainless steel is the ideal material because it is:

- Easy to clean and won’t peel or chip

- Resistant to corrosion from sanitizers or cleaning agents

- Compliant with GMP and HACCP hygiene requirements

Powder-coated units are only suitable for electronics or dry, technical areas.

4. How is a HEPA Box validated during a HACCP audit?

To pass audits from clients or certifiers, a HEPA Box should be regularly validated by checking:

- Differential pressure across the filter (via pressure gauge)

- Filtration performance (tested using aerosol or dispersed light methods)

- Leak test, gap sealing, and dust-retention prevention design

- Cleanability, including material inspection, corner finish, and surface quality

7. Need Help Choosing a HACCP-Compliant HEPA Box?

Selecting the right air filtration solution helps your facility not only meet food safety requirements but also pass international audits like BRC, ISO 22000, or FSSC with confidence.

VCR offers a complete HEPA Box solution for the food industry:

- Design consultation based on your factory layout

- Supply of stainless steel HEPA Boxes tailored to HACCP standards

- Full support on installation, validation, and operational guidance

Hotline: 090.123.9008

Email: [email protected]

Website: https://hepabox.vn/

Diep VCR